-

How to Maintain an EDM Machine Properly? -2026 -02-27Proper EDM Machine Maintenance Extends Lifespan and Precision The most effective way to maintain an EDM Machine is through consistent preventive maintenance—regular dielectric fluid management, electrode system inspection, electrical component checks, and strict cleanliness control. When maintained properly, an EDM Ma...

-

Why Engraving and Milling Machines Are a Game Changer for Manufacturing? -2026 -02-20Why Engraving and Milling Machines Are a Game Changer for Manufacturing Engraving and milling machines are essential tools in modern manufacturing, offering precision, versatility, and efficiency in creating detailed designs and complex shapes. These machines are used in various industries, from automotive and aerospa...

-

CNC EDM Die Sinking Machine: Is It the Best Choice for Precision Mold Making? -2026 -02-13Is a CNC EDM Die Sinking Machine the Best Solution for High-Precision Mold Manufacturing? The short answer is yes. A CNC EDM Die Sinking Machine is one of the most reliable solutions for producing complex cavities, sharp internal corners, and ultra-precise mold details that traditional machining cannot achieve. With p...

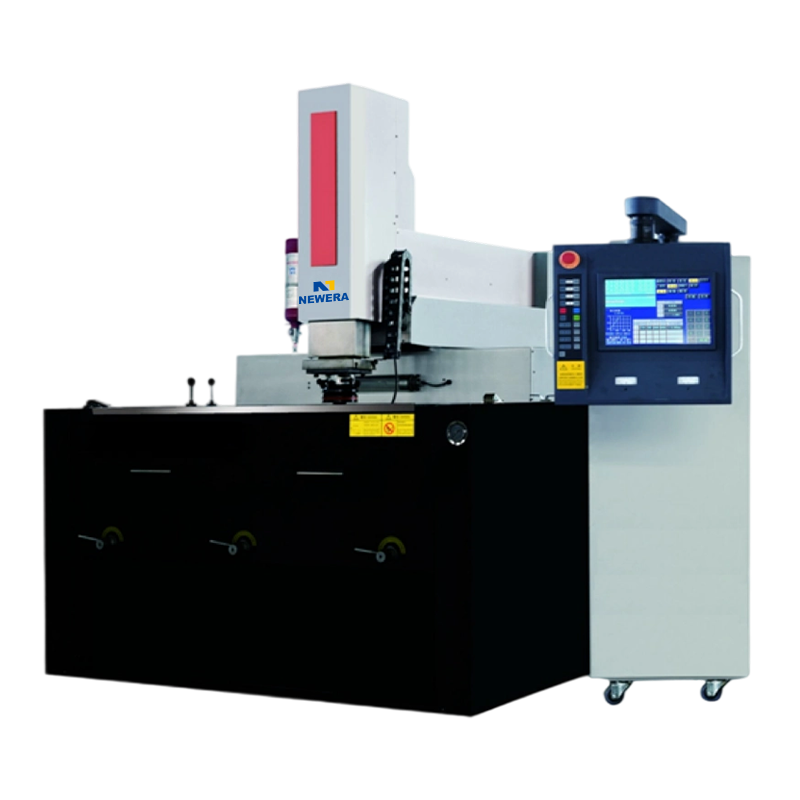

EDM Machine Manufacturers

Die Sinking EDM Machine, also known as EDM or Die Sinker EDM, is a precision machining process primarily used for manufacturing molds, dies, and complex cavities. This method operates on the principle of electrical discharge machining (EDM), where material is removed from a workpiece through a series of rapidly recurring electrical sparks between an electrode and the workpiece submerged in dielectric fluid. Material removal is achieved through controlled spark erosion, allowing for the machining of intricate geometries and hard materials regardless of their hardness.

As a professional OEM EDM Machine Manufacturers and ODM EDM Die Sinker Machine Company, New Era has continuously obtained the advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and mounting center.We always provide customers with the best solutions and creates the maximum value with high-quality products and perfect services.

Electrical Discharge Machining (EDM) is a precision machine tool that uses the principle of electrical discharge to process metal. It primarily removes material and shapes it to the desired form and size through the electrical discharge between electrodes and the workpiece. EDM does not require contact with the workpiece, thus enabling the processing of materials with extremely high hardness. It is widely used in mold manufacturing, aerospace, and automotive manufacturing.

1. Working Principle of EDM

The working principle of an EDM machine tool is based on the thermal effect of electrical discharge. When current flows between the electrode and the workpiece surface, a high temperature is instantly generated, causing localized melting or even vaporization of the workpiece surface, thereby removing the metal material. This process is performed through continuous electrical discharge pulses. EDM is generally divided into two types: pulse discharge and continuous discharge.

2. Types of EDM Machine Tools

There are two main types of EDM machine tools: wire EDM and sinking EDM.

Wire EDM (Electrical Discharge Machining): Uses a thin metal wire as an electrode to perform precision cutting through electrical discharge. It is suitable for machining complex-shaped molds or precision parts.

Sinking EDM (Electrical Discharge Molding): Uses pre-designed electrodes for machining. Suitable for engraving, hole machining, and other high-precision shape machining of precision molds.

3. Advantages of EDM Machines

(1) Applicability to High-Hardness Materials: EDM is not limited by material hardness and can process high-hardness materials such as cemented carbide and tool steel, making it particularly important in mold making and precision machining.

(2) High Precision: EDM machines can achieve micron-level machining accuracy, making them particularly suitable for machining complex geometries.

(3) No Mechanical Cutting Force Required: Since EDM removes material through electrical discharge, it does not require direct contact between the tool and the workpiece, thus avoiding the stress, deformation, and vibration associated with mechanical cutting.

(4) Applicability to Complex Shapes and Micro-machining: Electrical discharge machining (EDM) can handle complex internal cavities, small holes, and micro-parts, making it suitable for tasks that traditional cutting methods cannot accomplish.

4. Application Areas of EDM Machine Tools

EDM machine tools are widely used in many high-end manufacturing fields, mainly including:

Mold Manufacturing: Used for machining molds of various complex shapes, especially suitable for machining hard mold steel.

Precision Parts Machining: Used for machining high-precision parts in industries such as aerospace, automotive, and electronics.

Metal Engraving and Hole Machining: In some special processes, EDM can complete highly difficult engraving and hole machining tasks.

High-Precision Machining: For some parts with high precision requirements, such as gears and molds, EDM can provide extremely high machining accuracy.

| Application Areas | Description |

| Mold Manufacturing | Precision mold hole machining, engraving, and detail processing |

| Aerospace | Precision machining of high-hardness alloys and aerospace components |

| Automotive Manufacturing | Forming, drilling, and engraving of complex parts |

| Medical Devices | Machining of precision medical device parts |

| Electronics Manufacturing | Machining of precision micro-parts and complex shapes |

5. Maintenance and Care of EDM Machine Tools

Electrode Replacement: The electrodes used in EDM machine tools will gradually wear down during machining, so regular inspection and replacement of the electrodes are necessary to ensure machining accuracy.

Hydraulic System Maintenance: The hydraulic system of the EDM machine tool needs to be kept in good condition to avoid pressure fluctuations affecting the machining effect. Cooling System Maintenance: Keep the coolant clean and maintain an appropriate flow rate, preventing excessive impurities from entering the cooling system to ensure effective cooling and extend equipment life.

Nantong New Era Technology Co., LTD specializes in developing, designing and producing numerical control machine and CNC machine tool for more than 20 years. We have a professional team in technology development, manufacturing and sales services.

Electrical Discharge Machining (EDM) machines are extremely precise devices with broad application prospects, capable of meeting the demands of machining high-precision, high-hardness materials. Although their machining speed is relatively slow, EDM machines offer irreplaceable advantages in many fields, especially mold making, aerospace, and precision parts machining. With continuous technological advancements, the performance and efficiency of EDM machines are expected to further improve, playing a vital role in even more industrial sectors in the future.

русский

русский عربى

عربى