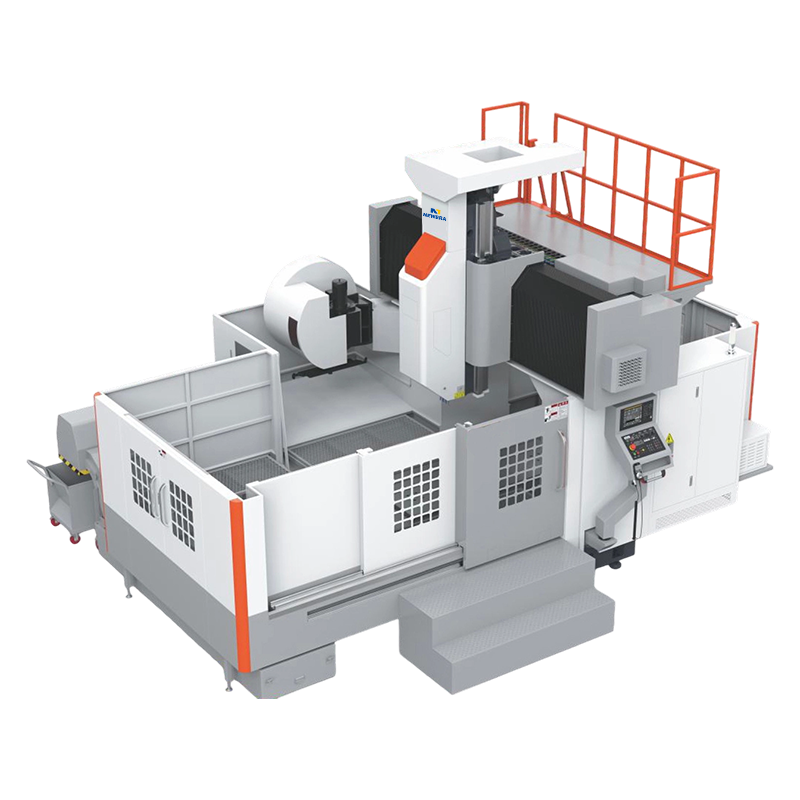

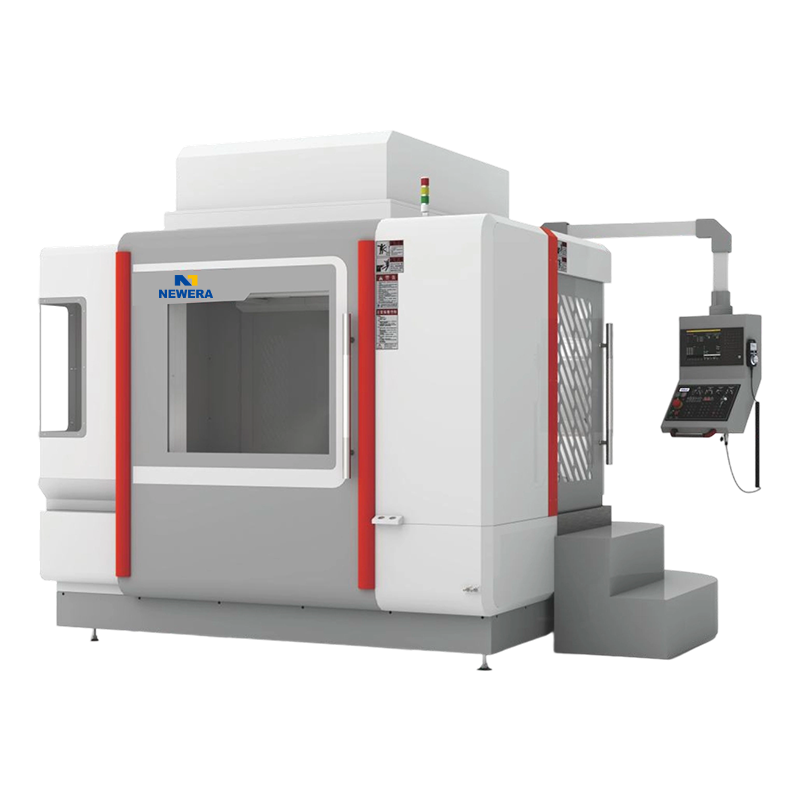

PRODUCT

ABOUT US

NANTONG NEW ERA TECHNOLOGY CO., LTD

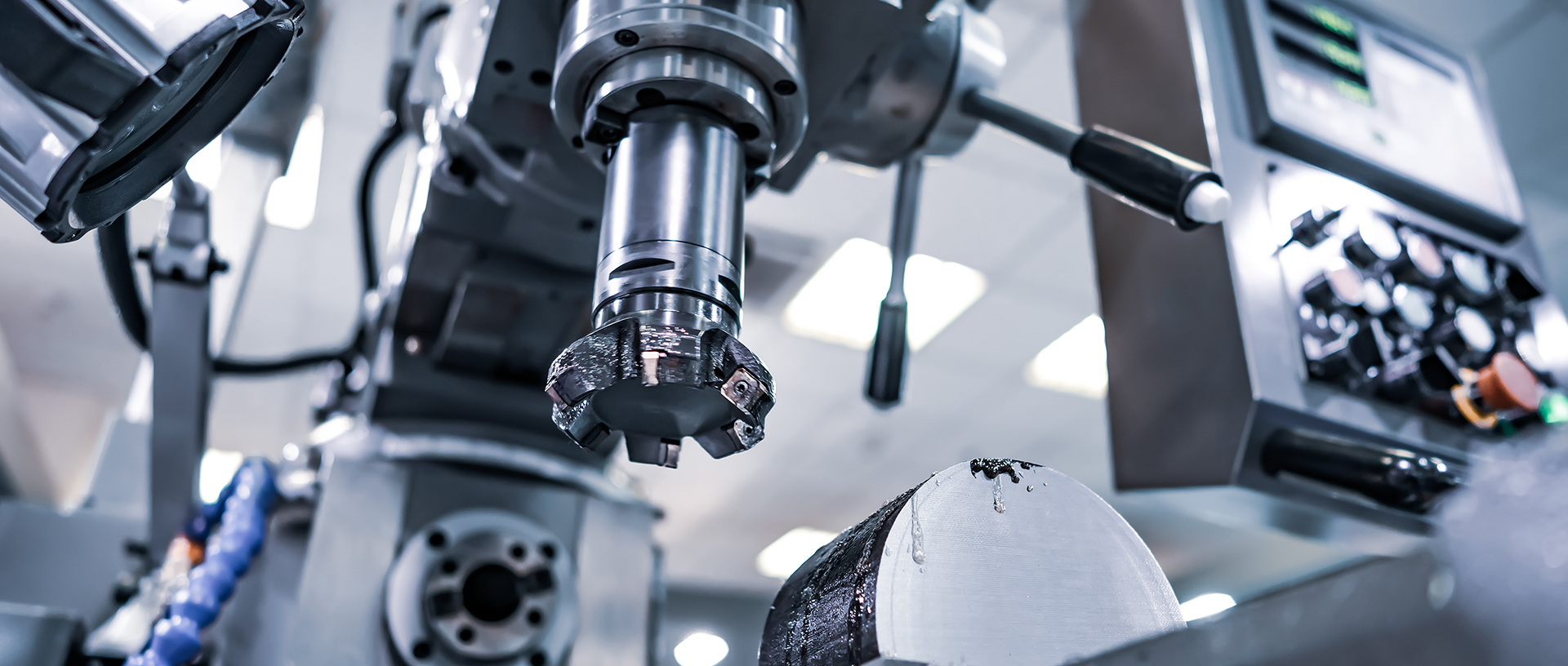

Nantong New Era Technology Co., Ltd. has been engaged in the development, design, and production of CNC

machine tools for over 20 years. We have a professional technical development, manufacturing, and sales

service team. It is a professional

ABOUT MORE

CNC machines Center manufacturers and machining center factory in China

.

-

0㎡

0㎡Factory Area

-

0+

0+Production Workshop

-

0+

0+Industry Experience

-

0+

0+Number of Employees

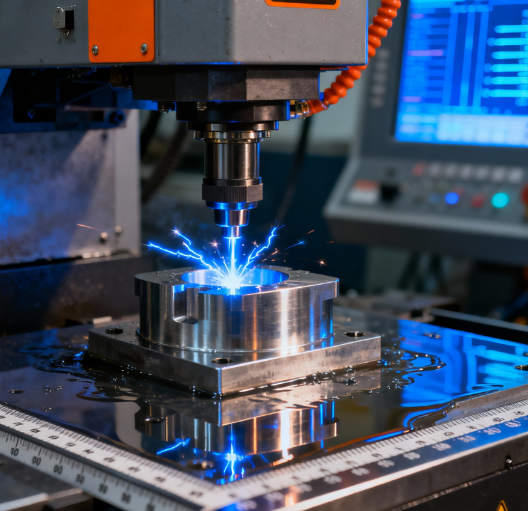

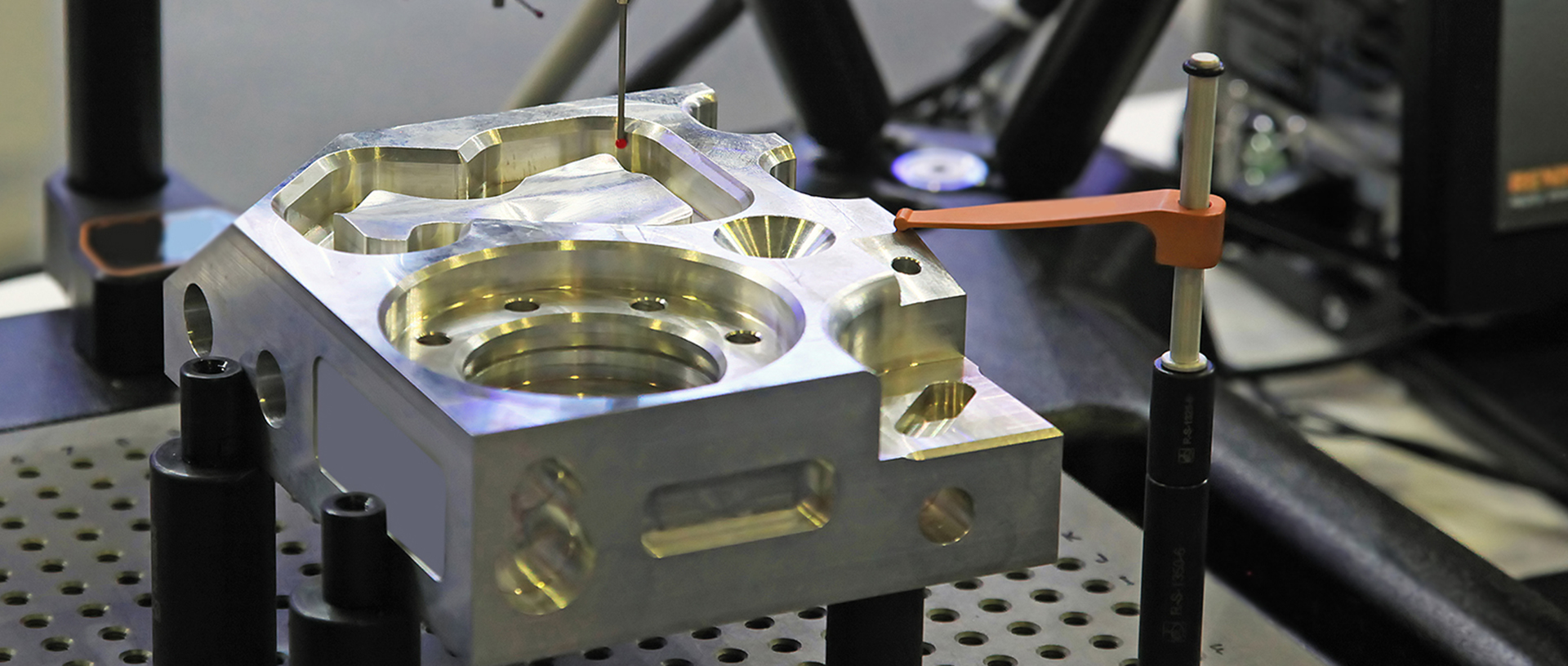

Precision Mold

Automotive

Electronic Communication

Precision Component Manufacturing

Aerospace

WHY CHOOSE US

OUR ADVANTAGES

-

1

Quality Assurance

Strict quality control system & team, high reputation in the market.

-

2

Good Service

Offer trainings of machine operation and maintenance, as well as basic programming.

-

3

Production Experience

Designing and producing numerical control machine and CNC machine tool for more than 20 years.

-

4

Sales Services

We have a professional team in technology development, manufacturing and sales services.

-

5

Product quality

Our products have been tested by the market and well received by customers.

-

6

Customer service

We are always customer-centric and provide a full range of pre-sales, sales and after-sales services.

LATEST UPDATES

WHAT'S NEWS

русский

русский عربى

عربى