-

How to Maintain an EDM Machine Properly? -2026 -02-27Proper EDM Machine Maintenance Extends Lifespan and Precision The most effective way to maintain an EDM Machine is through consistent preventive maintenance—regular dielectric fluid management, electrode system inspection, electrical component checks, and strict cleanliness control. When maintained properly, an EDM Ma...

-

Why Engraving and Milling Machines Are a Game Changer for Manufacturing? -2026 -02-20Why Engraving and Milling Machines Are a Game Changer for Manufacturing Engraving and milling machines are essential tools in modern manufacturing, offering precision, versatility, and efficiency in creating detailed designs and complex shapes. These machines are used in various industries, from automotive and aerospa...

-

CNC EDM Die Sinking Machine: Is It the Best Choice for Precision Mold Making? -2026 -02-13Is a CNC EDM Die Sinking Machine the Best Solution for High-Precision Mold Manufacturing? The short answer is yes. A CNC EDM Die Sinking Machine is one of the most reliable solutions for producing complex cavities, sharp internal corners, and ultra-precise mold details that traditional machining cannot achieve. With p...

As a professional OEM CNC Machines Suppliers and ODM Machine Tools Company, New Era has continuously obtained the advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and mounting center.We always provide customers with the best solutions and creates the maximum value with high-quality products and perfect services.

CNC machine tools are automated mechanical equipment controlled by computer programs. During machining, they can automatically control the machine tool's motion trajectory and cutting parameters according to a predetermined program, achieving high-precision and high-efficiency machining. CNC machine tools are widely used in industries such as aerospace, automotive, and mold manufacturing, and are an important basic equipment in modern manufacturing.

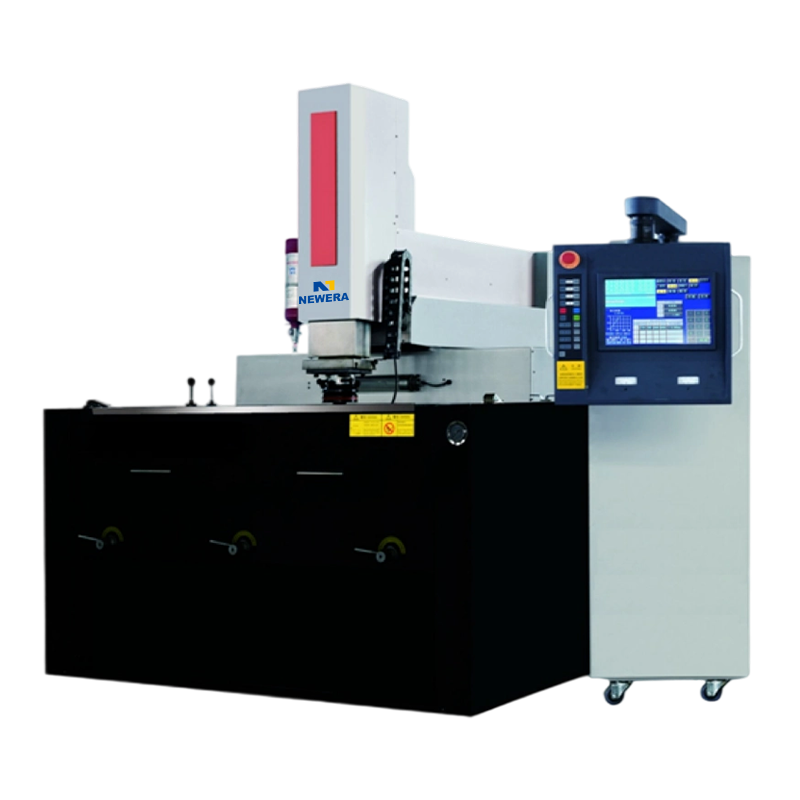

1. EDM Die Sinking Machine

An electrical discharge machining die sinking machine is a machine tool that uses the principle of electrical discharge machining for precision sinking. It is mainly used for deep hole drilling in the mold industry, especially suitable for sinking hard materials, and can obtain high precision and smooth hole walls.

Product Features:

Machining Materials: Difficult-to-machine materials such as cemented carbide and high-speed steel.

High Precision: Micron-level hole diameter control is possible.

Applications:Mold industry, aerospace, and other industries requiring high precision.

Working Principle:The EDM (Electrical Discharge Machining) die countersinking machine removes the metal layer from the workpiece surface through electrical discharge between the electrode and the workpiece, thus forming the required hole diameter and depth.

| Features | Description |

| Precision | Micrometer level |

| Machining speed | Relatively slow |

| Applicable materials | Carbide, high-speed steel, etc. |

| Application areas | Mold manufacturing, aerospace, precision parts machining |

2. Vertical Machining Center

A vertical machining center is a CNC machine tool with its spindle perpendicular to the worktable. It is suitable for drilling, milling, and other machining operations on parts. It has a compact structure, is easy to operate, and is widely used in mass production of parts.

Product Features:

High Machining Accuracy: Suitable for machining complex parts.

Multifunctional: Supports multiple processes such as milling, drilling, and tapping.

Application Scope: Precision parts, small-batch production.

Working Principle: Through the programming control of the CNC system, the vertical machining center achieves multi-axis linkage machining, enabling precise completion of different process steps.

| Features | Description |

| Machining Accuracy | High |

| Machining Methods | Milling, Drilling, Tapping, etc. |

| Applicable Materials | Aluminum, Steel, Stainless Steel, etc. |

| Application Areas | Precision mechanical parts, electronic parts machining |

3. Gantry Machining Center

A gantry machining center is a CNC machine tool with a gantry structure. The spindle support spans the workpiece, supported on both sides. It is typically used for machining large or heavy workpieces, capable of five-axis linkage, and offers very high machining accuracy and rigidity.

Product Features:

Large Machining Range: Suitable for machining large workpieces.

High Rigidity: Can withstand large cutting forces, suitable for heavy cutting.

High Precision: Strong precision machining capabilities, meeting the needs of high-end industries such as aerospace.

Working Principle: The gantry machining center achieves machining of large workpieces through free movement along the X, Y, and Z axes. Its structure allows for precise machining of the workpiece over a wider range.

4. Horizontal Machining Center

The horizontal machining center has a horizontally positioned spindle, suitable for machining heavy workpieces, especially suitable for batch production and high-efficiency production. It provides high cutting efficiency and long tool life.

Features:

High Efficiency: Suitable for mass production.

Stable Structure: Suitable for machining heavy workpieces.

Automation: Usually equipped with an automatic tool changer system to improve work efficiency.

Working Principle: The horizontal machining center uses a horizontally rotating spindle to contact the workpiece, providing higher machining efficiency and accuracy, and is often used for machining heavy workpieces.

| Features | Description |

| Machining Efficiency | High |

| Spindle Direction | Horizonta |

| Machining Accuracy | Medium |

| Application Areas | Large parts, aerospace, automotive, etc. |

5. Engraving Milling Machine

Engraving milling machines are mainly used for processing complex shapes, suitable for fine craftsmanship and engraving, and widely used in the processing of molds, artworks, and electronic components. It combines the features of milling machines and engraving machines, enabling various types of precision machining.

Product Features:

Precision Engraving: Suitable for engraving complex patterns and shapes.

Multifunctional: Can perform milling, engraving, drilling, and other operations.

Applications: Mold, craft, and decorative object processing.

Working Principle: Engraving milling machines use CNC technology, combining milling and engraving functions, to perform detailed engraving and cutting on the workpiece surface through the movement of the cutting tool.

6. Grinding Machines, Milling Machines, and Drilling Machines

Grinding machines, milling machines, and drilling machines are common basic equipment in CNC machine tools, each with different processing characteristics:

Grinding Machines: Used for high-precision surface grinding, especially suitable for materials with high hardness. They can achieve extremely high surface finishes.

Milling Machines: Used for milling operations, mainly cutting metal workpieces, and have strong versatility.

Drilling Machines: Mainly used for drilling and tapping, suitable for large-volume hole processing.

Product Features:

Grinding Machines: High precision, suitable for hard materials.

Milling Machines: Strong cutting ability, wide range of applications.

Drilling Machines: High efficiency, suitable for large-volume hole processing.

Nantong New Era Technology Co., LTD specializes in developing, designing and producing numerical control machine and CNC machine tool for more than 20 years. We have a professional team in technology development, manufacturing and sales services.

CNC machine tools come in a wide variety, suitable for precision machining in different fields. Whether it's high-precision machining of small parts or precision machining of heavy, large workpieces, there are suitable CNC machine tool models to meet different processing needs. In modern manufacturing, CNC machine tools have become key equipment for improving production efficiency and product accuracy.

русский

русский عربى

عربى