-

How to Maintain an EDM Machine Properly? -2026 -02-27Proper EDM Machine Maintenance Extends Lifespan and Precision The most effective way to maintain an EDM Machine is through consistent preventive maintenance—regular dielectric fluid management, electrode system inspection, electrical component checks, and strict cleanliness control. When maintained properly, an EDM Ma...

-

Why Engraving and Milling Machines Are a Game Changer for Manufacturing? -2026 -02-20Why Engraving and Milling Machines Are a Game Changer for Manufacturing Engraving and milling machines are essential tools in modern manufacturing, offering precision, versatility, and efficiency in creating detailed designs and complex shapes. These machines are used in various industries, from automotive and aerospa...

-

CNC EDM Die Sinking Machine: Is It the Best Choice for Precision Mold Making? -2026 -02-13Is a CNC EDM Die Sinking Machine the Best Solution for High-Precision Mold Manufacturing? The short answer is yes. A CNC EDM Die Sinking Machine is one of the most reliable solutions for producing complex cavities, sharp internal corners, and ultra-precise mold details that traditional machining cannot achieve. With p...

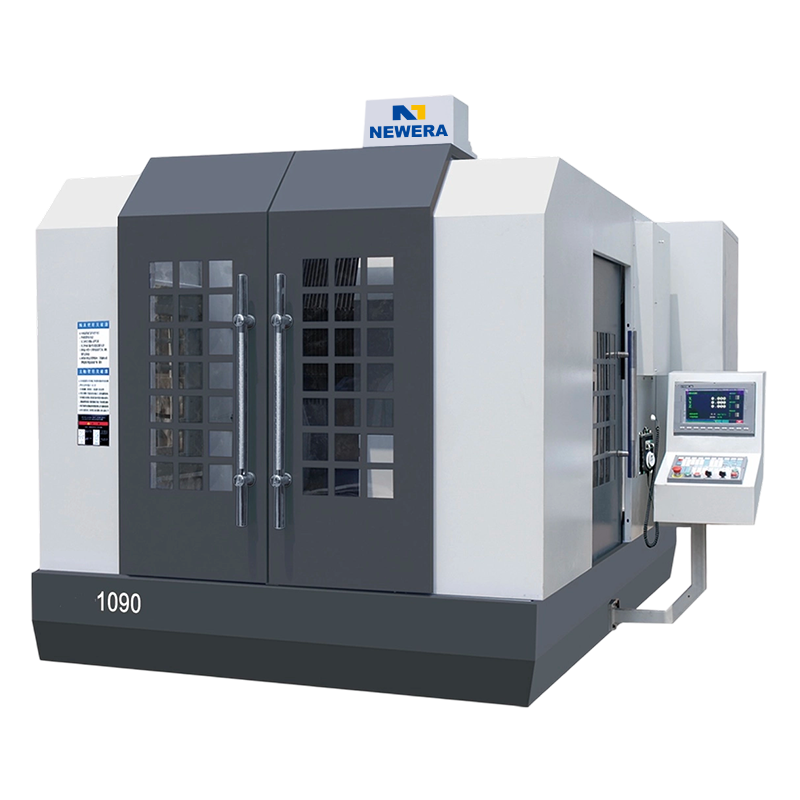

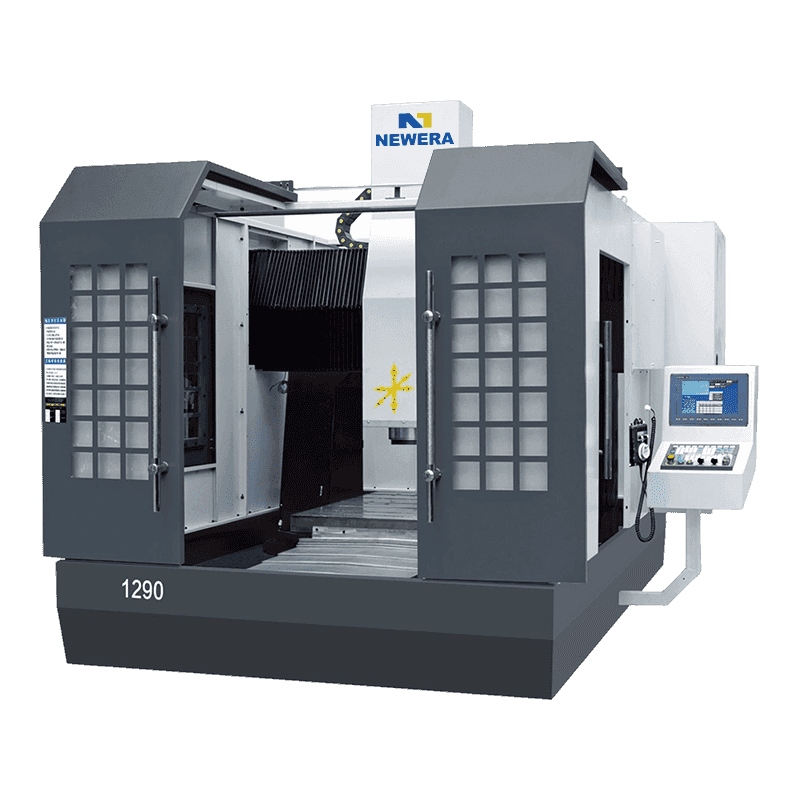

CNC Gantry Machining Center Suppliers

As a professional OEM CNC Gantry Machining Center Suppliers and ODM CNC Gantry Machining Center Factory, New Era has continuously obtained the advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and mounting center.We always provide customers with the best solutions and creates the maximum value with high-quality products and perfect services.

A CNC gantry machining center is a type of CNC machine tool widely used for machining large, high-precision parts. Compared to traditional vertical or horizontal machining centers, gantry machining centers employ a unique gantry-style structural design, providing greater rigidity, a larger machining space, and higher machining accuracy. It is widely used in aerospace, automotive, heavy machinery, and mold manufacturing industries, and is particularly suitable for machining large, complex-shaped, and multi-faceted parts.

As a professional OEM CNC Gantry Machining Center Suppliers and ODM CNC Gantry Machining Center Factory, New Era has continuously obtained the advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and mounting center.

1. Working Principle of a CNC Gantry Machining Center

The working principle of a CNC gantry machining center is similar to that of a traditional CNC machine tool. Machining is primarily achieved by controlling the various motion axes (X, Y, Z axes) of the machine tool through a CNC system. The core of its working principle lies in the gantry structure design, which allows the worktable to support large workpieces and enables precise machining operations through the movement of the machine tool.

The "gantry" structure is the most distinctive feature of a CNC gantry machining center. Its main machine tool frame consists of two columns and a crossbeam, forming a gantry-shaped structure, with the workpiece mounted on a fixed worktable. The cutting tool is controlled by the spindle system, completing the machining operation through movement along the X, Y, and Z axes. The free movement of the crossbeam between the two columns provides a larger machining range and space.

2. Advantages and Features of CNC Gantry Machining Centers

(1) Large Machining Space and High Rigidity

Due to its gantry structure, the CNC gantry machining center provides a larger machining space, suitable for machining large workpieces. The gantry structure effectively distributes the machine tool's workload, improves its rigidity, reduces deformation caused by cutting forces during machining, and ensures high-precision machining.

(2) High-Precision Machining

The CNC gantry machining center achieves high-precision machining through a high-precision CNC system and advanced transmission devices. Its spindle system and feed system are rigorously designed to precisely control the tool feed path, thereby ensuring the machining accuracy and surface quality of the parts.

(3) Adaptability to Complex Workpiece Machining

The gantry machining center can not only perform traditional milling but also complex multi-face machining. Due to its large worktable and machining stroke, it can accommodate and process large or complex-shaped parts, such as machine tool beds and large molds. Furthermore, CNC gantry machining centers often support five-axis simultaneous machining, enabling more complex three-dimensional surface machining.

(4) High Efficiency and Automation

Modern CNC gantry machining centers are typically equipped with automatic tool changers, capable of automatically changing tools according to different workpiece machining requirements. This not only improves machining efficiency but also reduces manual operation time and potential errors.

3. Key Maintenance Points for CNC Gantry Machining Centers

Regular maintenance and upkeep are crucial to ensure the normal operation and long-term stability of CNC gantry machining centers. The following are some key maintenance points:

(1) Regular Inspection and Cleaning

After each day's use, the machine tool should be cleaned to remove oil, dust, and cutting chips from the machine tool surface, especially the guideways, lead screws, and spindle components. Regular cleaning not only extends the service life of the equipment but also prevents damage to precision components from debris.

(2) Lubrication System Inspection

The spindle, guideways, and lead screw of a CNC gantry machining center all require lubrication. The quality and quantity of the lubricating oil should be checked regularly, and the oil should be replaced according to the machine tool's instruction manual. Inadequate lubrication can lead to component wear, decreased accuracy, and even serious malfunctions.

(3) Guideway and Lead Screw Inspection and Maintenance

The guideways and lead screws of a gantry machining center are key components for machine tool accuracy. Regularly check the wear of the guideways to ensure their smoothness and flatness, avoiding errors caused by guideway friction. Regularly inspect the lead screw to ensure the clearance between the lead screw and nut meets requirements to maintain feed accuracy.

(4) Spindle System Inspection

The spindle is one of the core components of a CNC gantry machining center. Regularly check the spindle's bearings, cooling system, and sealing performance to ensure normal operation. If abnormal noise or vibration is detected in the spindle, it should be inspected and repaired immediately to prevent spindle failure.

(5) Inspection of Electrical System

Regularly inspect the CNC system, electrical cabinet, servo motors, drives, and other electrical components to ensure the stability and safety of the electrical system. Inspect cables and connecting wires to prevent wear, aging, and other problems, ensuring the safe operation of the machine tool.

CNC gantry machining centers, with their advantages of high precision, high rigidity, and large machining space, have become indispensable equipment in various manufacturing industries. They can not only machine complex shapes and large-sized parts, but also achieve efficient, multi-faceted machining, and are widely used in aerospace, automotive, and mold manufacturing fields. To ensure the long-term stable operation of CNC gantry machining centers, regular maintenance and upkeep are essential. Careful inspection and maintenance can extend the service life of the equipment and maintain its high-precision machining capabilities.

русский

русский عربى

عربى