-

How to Maintain an EDM Machine Properly? -2026 -02-27Proper EDM Machine Maintenance Extends Lifespan and Precision The most effective way to maintain an EDM Machine is through consistent preventive maintenance—regular dielectric fluid management, electrode system inspection, electrical component checks, and strict cleanliness control. When maintained properly, an EDM Ma...

-

Why Engraving and Milling Machines Are a Game Changer for Manufacturing? -2026 -02-20Why Engraving and Milling Machines Are a Game Changer for Manufacturing Engraving and milling machines are essential tools in modern manufacturing, offering precision, versatility, and efficiency in creating detailed designs and complex shapes. These machines are used in various industries, from automotive and aerospa...

-

CNC EDM Die Sinking Machine: Is It the Best Choice for Precision Mold Making? -2026 -02-13Is a CNC EDM Die Sinking Machine the Best Solution for High-Precision Mold Manufacturing? The short answer is yes. A CNC EDM Die Sinking Machine is one of the most reliable solutions for producing complex cavities, sharp internal corners, and ultra-precise mold details that traditional machining cannot achieve. With p...

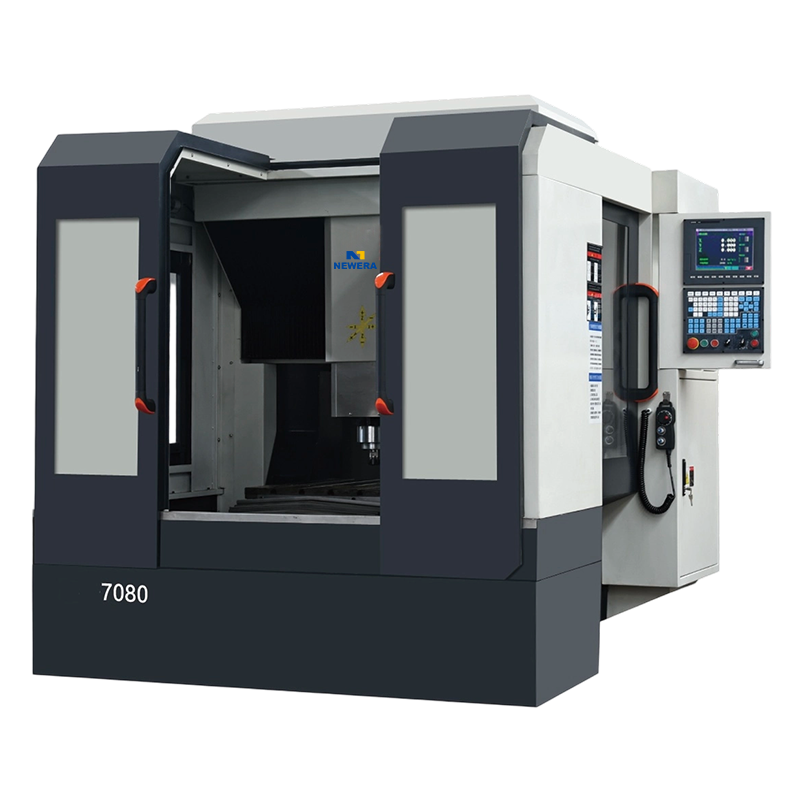

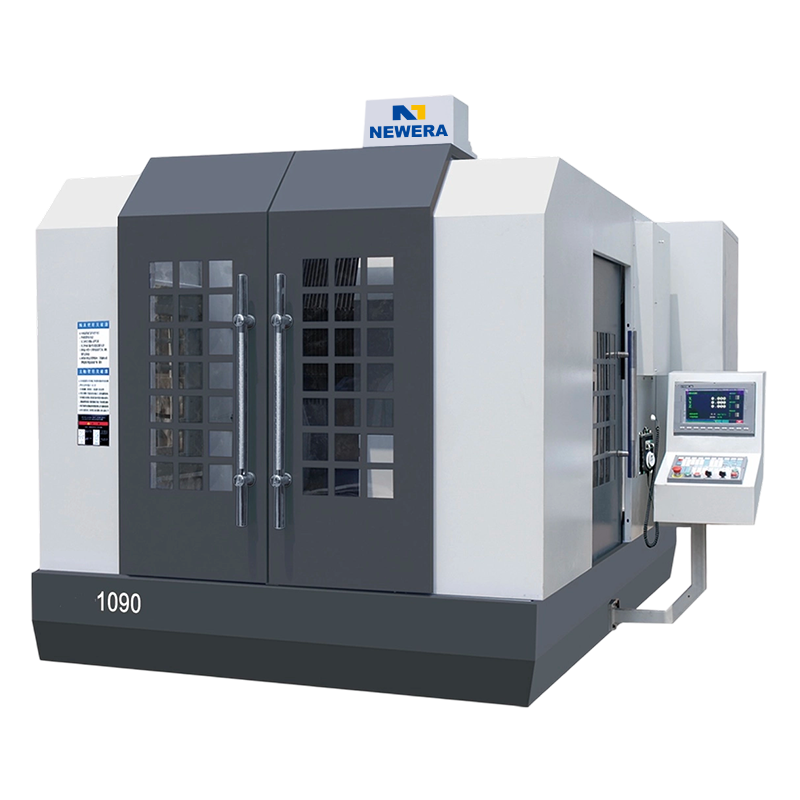

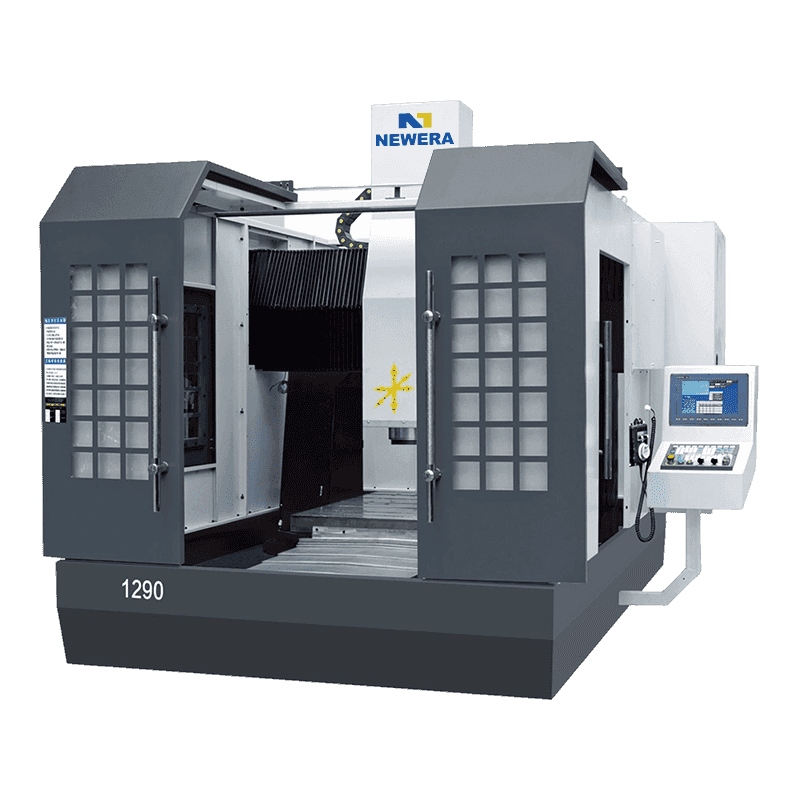

Engraving and Milling Machine Suppliers

An Engraving and Milling Machine is a versatile CNC device that combines precise milling and detailed engraving capabilities. It uses a high-speed spindle to cut, carve, and etch intricate designs, lettering, and patterns into materials like metal, wood, plastic, and composites. Its key advantage is performing both heavy-duty milling and fine, high-resolution engraving on a single platform, making it ideal for prototyping, signage, and mold-making.

As a professional OEM Engraving and Milling Machine Suppliers and ODM Engraving and Milling Machine Company, New Era has continuously obtained the advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and mounting center.We always provide customers with the best solutions and creates the maximum value with high-quality products and perfect services.

An engraving and milling machine is a CNC machine tool specifically designed for high-precision engraving and milling operations. It is widely used in mold manufacturing, electronic product processing, jewelry making, and automotive parts manufacturing. Engraving and milling machines can not only perform complex engraving tasks but also have milling capabilities, meeting the demands for high-precision, detailed engraving and complex part machining. Their machining accuracy typically reaches the micron level, making them suitable for tasks such as small hole machining, text engraving, and curve cutting.

1. Basic Structure and Working Principle of Engraving and Milling Machines

The structure of an engraving and milling machine mainly consists of a bed, worktable, spindle, CNC system, and tool magazine. Its spindle can rotate at high speed, carrying suitable cutting tools for detailed engraving and milling operations. The working principle of an engraving and milling machine is similar to that of a traditional milling machine, utilizing the CNC system to control the precise movement of the X, Y, and Z axes, and performing engraving and cutting operations through preset machining programs.

Engraving and milling machines typically have high precision, capable of completing complex curved surfaces, internal cavities, small holes, and intricate engraving patterns. Through the CNC system, users can input detailed engraving patterns or CAD files, and the machine tool will automatically engrave according to the set path, greatly improving the automation level and processing efficiency.

2. Main Features of Engraving Milling Machines

(1) High-precision engraving: Engraving milling machines can provide micron-level processing accuracy, suitable for fine processing and engraving tasks with complex geometries, and are widely used in the processing of high-precision parts and complex patterns.

(2) Multifunctionality: In addition to engraving, engraving milling machines can also perform milling, drilling, hole punching, and other processing operations to adapt to different processing needs.

(3) Suitable for small workpieces: Engraving milling machines are generally suitable for processing small, precision workpieces, especially those with complex details and precision requirements, such as jewelry and mobile phone accessories.

(4) Highly efficient automation: Engraving milling machines are equipped with a CNC system, which can automatically change tools and execute preset programs, greatly improving production efficiency and reducing manual intervention.

(5) Strong adaptability: They can be used for engraving processing on a variety of materials, including metals, plastics, wood, ceramics, etc., meeting the processing needs of different industries.

3. Application Areas of Engraving Milling Machines

Due to their high precision and multifunctionality, engraving milling machines are widely used in multiple fields:

(1) Mold Manufacturing: In the mold making process, engraving milling machines can precisely process complex mold parts, especially in situations requiring detailed engraving, such as injection molds and die-casting molds.

(2) Electronics Industry: Engraving milling machines can process electronic components, such as mobile phone casings, keyboard panels, and circuit boards, meeting the requirements for fine processing and high precision.

(3) Jewelry Industry: In jewelry processing, engraving milling machines can be used to engrave fine textures, carvings, and patterns, especially suitable for high-end jewelry and personalized customization.

(4) Automotive Industry: Used to process automotive parts, such as dashboards, buttons, and decorative strips, enabling precise pattern engraving and hole processing.

(5) Medical Devices: Engraving milling machines can process precision medical device components, such as orthopedic surgical instruments and dental instruments, ensuring their processing accuracy and surface finish.

4. Common Faults and Solutions for Engraving Milling Machines

Although engraving milling machines offer high precision and efficiency, some common faults may occur during prolonged use. Timely detection and resolution of these problems helps improve machine tool efficiency and extend its service life. The following are common faults and solutions for engraving milling machines:

| Fault Type | Common Symptoms | Possible Causes | Solutions |

| Spindle Failure | Spindle not rotating, unstable speed, abnormal overheating | Power phase loss, inverter failure, bearing damage | Check three-phase power supply; reset inverter parameters; replace spindle bearings or motor. |

| Poor Engraving Accuracy | Dimensional deviation, contour burrs, inaccurate repeat positioning | Leader screw/guide rail wear, loose coupling, dull tool | Adjust lead screw backlash; tighten coupling; replace with sharp tool; calibrate stepper/servo motor. |

| Step Loss or Overshoot | Engraved graphic misalignment, uneven edges | Insufficient drive current, excessive acceleration, high mechanical resistance | Increase driver current; reduce acceleration parameters; clean and lubricate guide rails. |

| Tool Breakage | Frequent tool breakage, chipping | Excessive feed rate, excessive depth of cut, unstable material clamping | Reduce feed rate; perform layered cutting; check fixture rigidity. |

| Control system crash | Screen freeze, program interruption, no response | System overheating, virus interference, insufficient memory | Restart the control system; run an antivirus scan; optimize the machining program or upgrade hardware. |

Engraving milling machines, with their high precision, versatility, and high level of automation, are widely used in mold manufacturing, electronics, jewelry, automotive, and other industries, and are especially suitable for processing high-precision, small workpieces.

Nantong New Era Technology Co., Ltd. is a professional enterprise specializing in the R&D, design, and production of engraving milling machines. We have a professional team integrating technology R&D, manufacturing, and sales services. As a professional OEM engraving milling machine manufacturer, New Era continuously achieves advanced technological results both domestically and internationally, and has now developed into a professional manufacturer with a complete production and installation center.

русский

русский عربى

عربى