-

How to Maintain an EDM Machine Properly? -2026 -02-27Proper EDM Machine Maintenance Extends Lifespan and Precision The most effective way to maintain an EDM Machine is through consistent preventive maintenance—regular dielectric fluid management, electrode system inspection, electrical component checks, and strict cleanliness control. When maintained properly, an EDM Ma...

-

Why Engraving and Milling Machines Are a Game Changer for Manufacturing? -2026 -02-20Why Engraving and Milling Machines Are a Game Changer for Manufacturing Engraving and milling machines are essential tools in modern manufacturing, offering precision, versatility, and efficiency in creating detailed designs and complex shapes. These machines are used in various industries, from automotive and aerospa...

-

CNC EDM Die Sinking Machine: Is It the Best Choice for Precision Mold Making? -2026 -02-13Is a CNC EDM Die Sinking Machine the Best Solution for High-Precision Mold Manufacturing? The short answer is yes. A CNC EDM Die Sinking Machine is one of the most reliable solutions for producing complex cavities, sharp internal corners, and ultra-precise mold details that traditional machining cannot achieve. With p...

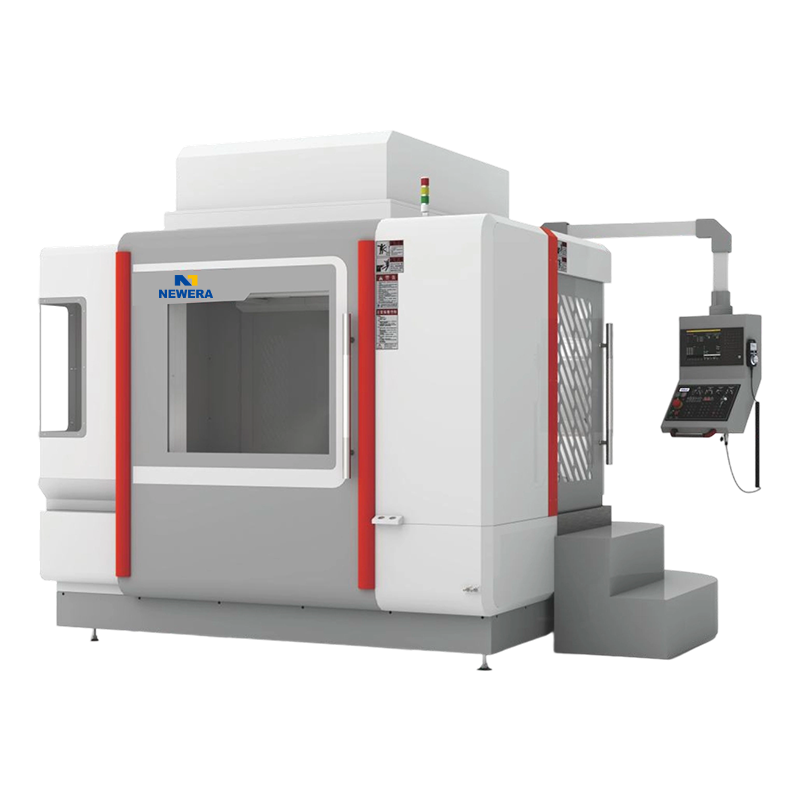

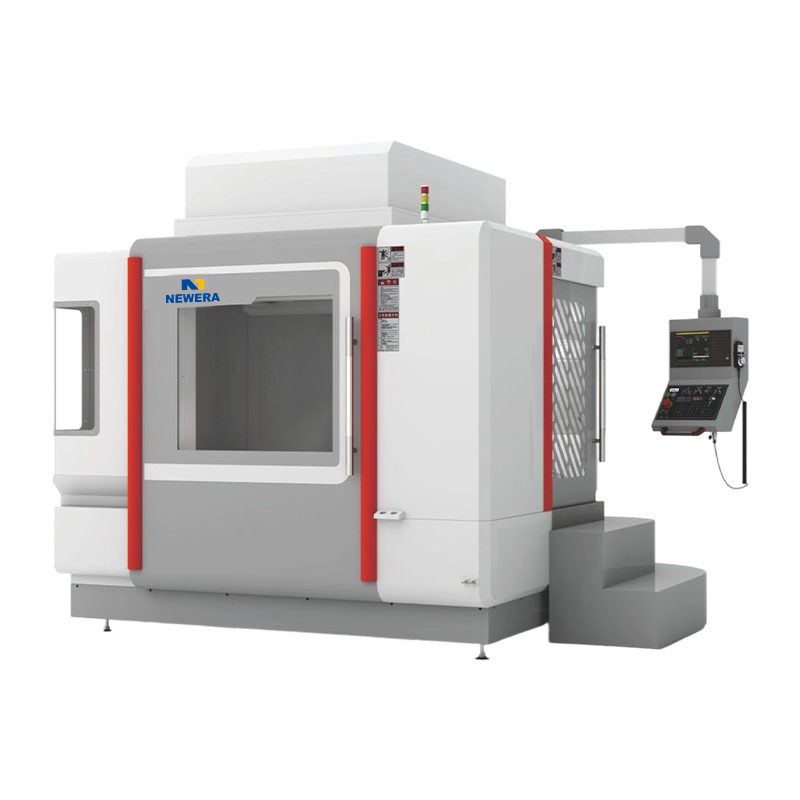

Horizontal Machining Center Suppliers

A Horizontal Machining Center (HMC) is a CNC machine tool with a horizontally oriented spindle.Its key feature is a rotary pallet changer, which enables automatic, uninterrupted machining of multiple sides of a part in a single setup, making it ideal for high-volume production of complex components like engine blocks and gearboxes.It is often used in high-speed precision milling and drilling operations.

As a professional OEM Horizontal Machining Center Suppliers and ODM HMC machine Factory, New Era has continuously obtained the advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and mounting center.We always provide customers with the best solutions and creates the maximum value with high-quality products and perfect services.

A horizontal machining center (HMC) is a CNC machine tool characterized by a horizontal spindle. Compared to vertical machining centers, the spindle of a horizontal machining center is parallel to the worktable, allowing it to better handle heavier workpieces and more complex cutting tasks. Due to its superior stability and cutting capabilities, horizontal machining centers are widely used in machining fields requiring high precision and efficiency, such as automotive, aerospace, mold manufacturing, and heavy machinery processing.

1. Basic Structure and Working Principle of a Horizontal Machining Center

The main structure of a horizontal machining center includes the bed, worktable, spindle, tool magazine, CNC system, and servo system. Its horizontally arranged spindle can withstand large cutting forces, making it suitable for high-load, high-cutting-force machining tasks. The worktable is usually equipped with a rotatable function, allowing for flexible workpiece positioning and multi-angle machining.

The horizontal machining center precisely controls the movement of the X, Y, and Z axes through the CNC system and completes various machining operations, such as milling, drilling, and tapping, through program settings. Compared to vertical machining centers, horizontal machining centers have a more flexible worktable for multi-faceted machining, improving both efficiency and precision.

2. Main Features of Horizontal Machining Centers

(1) High Cutting Capacity: Due to the horizontal spindle arrangement, horizontal machining centers can withstand greater cutting forces, making them particularly suitable for machining heavier workpieces or performing heavy cutting tasks.

(2) Suitable for Multi-faceted Machining: The worktable of a horizontal machining center can rotate, enabling multi-angle machining of the workpiece, reducing the number of workpiece clamping operations and improving machining efficiency.

(3) High Rigidity and Stability: Horizontal machining centers possess high rigidity, capable of withstanding large machining loads, making them especially suitable for roughing and high-cutting-load machining tasks.

(4) Multifunctionality: In addition to conventional milling and drilling, horizontal machining centers typically have strong multi-axis linkage capabilities, enabling the machining of complex shapes and multiple processes to meet various technological requirements.

(5) High Degree of Automation: Many horizontal machining centers are equipped with automatic tool changers, which can automatically change various tools without manual intervention, improving production efficiency and machining precision.

3. Application Areas of Horizontal Machining Centers

Horizontal machining centers are widely used in many industries, especially in fields requiring high-load and high-precision machining.

(1) Automotive Industry: In automobile manufacturing, horizontal machining centers are used to process engine parts, gearboxes, body frames, and other components, efficiently handling complex workpieces in mass production.

(2) Aerospace: Horizontal machining centers are widely used in the machining of aero-engine components, wing frames, structural parts, etc., meeting the requirements of high-precision and high-load machining.

(3) Mold Manufacturing: Horizontal machining centers are suitable for machining large molds, especially performing excellently in the production of molds with complex shapes and high precision requirements.

(4) Machinery Manufacturing: Horizontal machining centers can efficiently machine large mechanical parts, such as machine tool beds and supports, meeting the machining needs of heavy and large-sized parts.

(5) Heavy Machinery: In the field of heavy machinery manufacturing, horizontal machining centers can provide powerful cutting forces, adapting to the efficient machining of roughing and complex parts.

4. Common Faults and Solutions for Horizontal Machining Centers

| Fault Type | Common Symptoms | Possible Causes | Solutions |

| Spindle System Fault | Excessive spindle vibration, rough machining, abnormal noise | Bearing wear, dynamic balancing failure, broaching mechanism failure | Replace spindle bearings; rebalance; check broaching force or replace disc springs. |

| Table Indexing Problem | Inaccurate indexing, rotational jamming, inability to lock | Insufficient hydraulic pressure, encoder failure, worn indexing gear | Adjust hydraulic pressure; calibrate encoder; repair or replace indexing gear. |

| Tool Changer Fault | Interrupted tool change, tool holder detachment, tool magazine misalignment | Weared robotic gripper jaws, insufficient air pressure, signal interference | Replace grippers; check air source pressure (≥0.6MPa); shield interference sources or rewire. |

| Coolant Leakage | Leakage in machining area, rapid drop in coolant level | Aging seals, ruptured pipes, damaged pump | Replace seals; repair pipes; check coolant pump sealing. |

| Fixture positioning abnormality | Workpiece displacement, insufficient clamping force | Low hydraulic fixture pressure, worn locating pins, program error | Adjust hydraulic pressure; replace locating pins; check fixture macro program. |

Horizontal machining centers, with their superior cutting capabilities, adaptability to multi-faceted machining, and high rigidity, are widely used in various industries, especially suitable for workpieces requiring high precision and heavy loads. Although some faults may occur during prolonged high-intensity use, timely inspection, maintenance, and adjustment can effectively prevent problems and extend the service life of the equipment. With continuous technological advancements, the performance of horizontal machining centers will continue to improve, better meeting the growing machining needs of various industries.

Nantong New Era Technology Co., Ltd. is a professional enterprise specializing in the R&D, design, and production of horizontal machining centers. We have a professional team integrating technology R&D, manufacturing, and sales services. As a professional OEM gantry machining center supplier and ODM gantry machining center manufacturer, New Era has continuously achieved advanced technological results both domestically and internationally, and has now developed into a professional manufacturer with a complete production and installation center.

русский

русский عربى

عربى