-

How to Maintain an EDM Machine Properly? -2026 -02-27Proper EDM Machine Maintenance Extends Lifespan and Precision The most effective way to maintain an EDM Machine is through consistent preventive maintenance—regular dielectric fluid management, electrode system inspection, electrical component checks, and strict cleanliness control. When maintained properly, an EDM Ma...

-

Why Engraving and Milling Machines Are a Game Changer for Manufacturing? -2026 -02-20Why Engraving and Milling Machines Are a Game Changer for Manufacturing Engraving and milling machines are essential tools in modern manufacturing, offering precision, versatility, and efficiency in creating detailed designs and complex shapes. These machines are used in various industries, from automotive and aerospa...

-

CNC EDM Die Sinking Machine: Is It the Best Choice for Precision Mold Making? -2026 -02-13Is a CNC EDM Die Sinking Machine the Best Solution for High-Precision Mold Manufacturing? The short answer is yes. A CNC EDM Die Sinking Machine is one of the most reliable solutions for producing complex cavities, sharp internal corners, and ultra-precise mold details that traditional machining cannot achieve. With p...

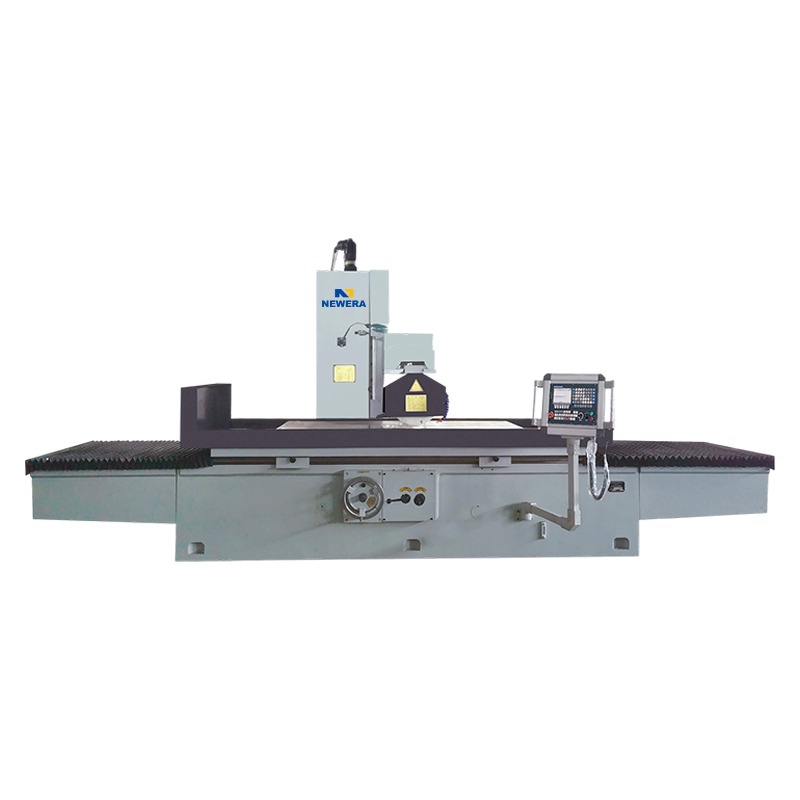

Program Controlled Surface Grinding Machine Manufacturers

As a professional OEM Program Controlled Surface Grinding Machine Manufacturers and ODM Program Controlled Surface Grinding Machine Factory, New Era has continuously obtained the advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and mounting center.We always provide customers with the best solutions and creates the maximum value with high-quality products and perfect services.

A program-controlled surface grinder (CNC surface grinder) is a high-precision grinder that is automatically controlled by a numerical control system (CNC). It is widely used in machinery manufacturing, mold processing, and precision mechanical parts machining. Compared to traditional manual surface grinders, program-controlled surface grinders have a higher level of automation, more stable machining accuracy, and stronger adaptability, making them particularly suitable for mass production and machining complex-shaped workpieces.

As a professional OEM program-controlled surface grinder manufacturer and ODM program-controlled surface grinder factory, New Era has continuously achieved advanced scientific and technological achievements both domestically and internationally, and has now developed into a professional manufacturer with a complete production and installation center. We always provide customers with the best solutions and create maximum value with high-quality products and perfect services.

1. Working Principle of a Program-Controlled Surface Grinding Machine

The working principle of a program-controlled surface grinder is similar to that of a traditional surface grinder; grinding is still performed through the contact between the grinding wheel on the grinder and the workpiece. However, the biggest difference of a program-controlled surface grinder lies in its precise control of various operations through a numerical control (NC) system, thereby achieving automated and precision machining.

(1) NC System Control

The core of a program-controlled surface grinder is its NC system, typically a high-precision NC system. The operator designs the workpiece machining drawings using CAD/CAM software and generates the corresponding NC program. These program instructions include the workpiece dimensions, shape, grinding sequence, feed rate, etc., and the NC system controls the grinder's movement according to these program instructions.

(2) Automated Feed and Grinding Process

The NC system precisely controls the movement of the X, Y, and Z axes, enabling the grinder to perform precise grinding along a set path. The grinding wheel rotates at high speed driven by the spindle, contacting the workpiece surface and removing material. Through a precise feed method, the flatness, smoothness, and precision of the workpiece surface are ensured.

(3) Cooling and Chip Removal with Cutting Fluid

Like traditional surface grinders, program-controlled surface grinders also require cutting fluid for cooling and lubrication to reduce cutting heat and chip accumulation, preventing temperature rise during machining from affecting the accuracy of the workpiece and grinding wheel. The cutting fluid system evenly sprays coolant onto the contact area between the grinding wheel and the workpiece through nozzles, ensuring smooth machining.

(4) Automatic Dressing and Error Compensation

Program-controlled surface grinders are typically equipped with automatic dressing devices that automatically dress and calibrate the grinding wheel, ensuring it remains in optimal cutting condition. Simultaneously, the CNC system can compensate for minor errors occurring during grinding in real time, ensuring the accuracy of workpiece dimensions.

2. Advantages and Features of Program-Controlled Surface Grinding Machines

(1) High-Precision Machining

Program-controlled surface grinders can precisely control the grinding process through a CNC system, achieving micron-level machining accuracy. High consistency is guaranteed in dimensions, shape, and surface finish, making them particularly suitable for mass production of precision parts.

(2) High Efficiency and Automation

Traditional surface grinders require extensive manual operation, while program-controlled surface grinders, through fully automated control of the CNC system, significantly improve processing efficiency, especially in mass production. The automated control system can automatically adjust parameters such as feed rate, grinding depth, and machining path according to different workpiece requirements, improving production efficiency and processing quality.

(3) Complex Workpiece Machining Capability

Traditional surface grinders are mostly used for simple surface grinding, while program-controlled surface grinders can handle more complex workpiece shapes. Through CNC programming, program-controlled surface grinders can perform various complex grinding operations on workpieces, including bevels, grooves, and stepped surfaces, meeting diverse processing needs.

3. Maintenance Points of Program-Controlled Surface Grinding Machines

The high precision and stability of program-controlled surface grinders rely on proper maintenance. Regular maintenance is essential to ensure long-term stable operation and maintain high machining accuracy. Here are some key maintenance points:

Regular Cleaning and Lubrication:

Cleanliness is fundamental to the normal operation of a program-controlled surface grinder. Regularly clean the worktable, guideways, spindle, grinding wheels, and other components to prevent the accumulation of grinding debris and impurities, which can affect machining accuracy. Simultaneously, regularly lubricate the guideways, lead screws, spindle, and other moving parts to prevent friction and wear.

Inspect Grinding Wheels and Spindle:

The wear of the grinding wheel directly affects machining accuracy and surface quality; therefore, it is necessary to regularly inspect the wear condition of the grinding wheel. If uneven wear or cracks appear on the grinding wheel, it should be replaced or repaired promptly. The spindle is also a core component of the grinder; regularly check its operation to ensure it runs smoothly without abnormal noise.

Machine Tool Calibration:

With increased use, the machining accuracy of program-controlled surface grinders may deviate. Regular accuracy calibration using precision measuring tools (such as laser interferometers and levels) is necessary to ensure the machine tool maintains optimal machining accuracy.

Cutting Fluid System Maintenance:

The cutting fluid system is crucial for the cooling and lubrication of the grinder. Regularly check the cutting fluid level, quality, and concentration, and replace the cutting fluid as needed. Simultaneously, the cutting fluid filtration system should be cleaned regularly to prevent impurities from contaminating the cutting fluid and affecting cooling performance.

русский

русский عربى

عربى