-

How to Maintain an EDM Machine Properly? -2026 -02-27Proper EDM Machine Maintenance Extends Lifespan and Precision The most effective way to maintain an EDM Machine is through consistent preventive maintenance—regular dielectric fluid management, electrode system inspection, electrical component checks, and strict cleanliness control. When maintained properly, an EDM Ma...

-

Why Engraving and Milling Machines Are a Game Changer for Manufacturing? -2026 -02-20Why Engraving and Milling Machines Are a Game Changer for Manufacturing Engraving and milling machines are essential tools in modern manufacturing, offering precision, versatility, and efficiency in creating detailed designs and complex shapes. These machines are used in various industries, from automotive and aerospa...

-

CNC EDM Die Sinking Machine: Is It the Best Choice for Precision Mold Making? -2026 -02-13Is a CNC EDM Die Sinking Machine the Best Solution for High-Precision Mold Manufacturing? The short answer is yes. A CNC EDM Die Sinking Machine is one of the most reliable solutions for producing complex cavities, sharp internal corners, and ultra-precise mold details that traditional machining cannot achieve. With p...

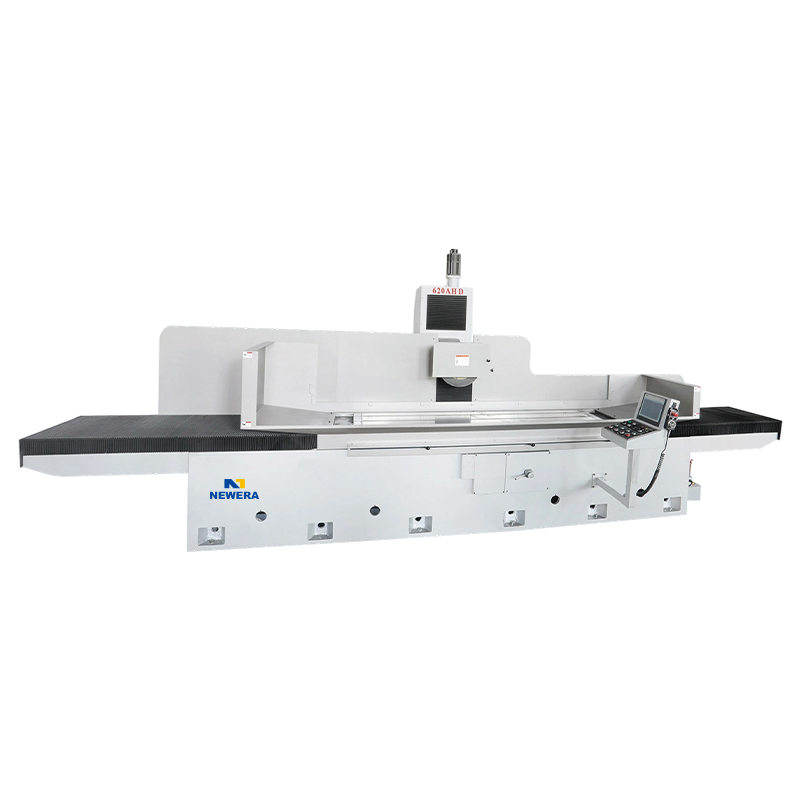

As a professional OEM Precision Surface Grinding Machine Manufacturers and ODM Precision Surface Grinding Machine Factory, New Era has continuously obtained the advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and mounting center.We always provide customers with the best solutions and creates the maximum value with high-quality products and perfect services.

A precision surface grinder is a device used for precision grinding of the surfaces of workpieces such as metals, plastics, and ceramics. It is mainly used for processing parts with high requirements for flatness, straightness, and shape accuracy. It is widely used in industries such as machinery manufacturing, mold processing, and electronic component manufacturing, and plays an irreplaceable role, especially in processing workpieces requiring high surface finish and flatness. Precision surface grinders not only improve processing accuracy but also enhance the surface quality of workpieces, enabling them to meet strict dimensional tolerance requirements.

1. Working Principle of Precision Surface Grinding Machines

The working principle of a precision surface grinder is to remove excess material from the workpiece surface through friction between the grinding wheel and the workpiece, thereby achieving the required flatness and precision. Its working process typically includes the following main steps:

(1) Workpiece Fixing

The workpiece is usually fixed to the worktable using a magnetic chuck or clamp to ensure that the workpiece does not change position during grinding. Magnetic chucks are generally used for ferromagnetic materials, providing strong adsorption force; for non-magnetic materials, special clamps are used for fixing.

(2) Grinding Wheel Contact with Workpiece

The grinding wheel of a precision surface grinder rotates at high speed via the spindle, contacting the workpiece surface for grinding. The grinder's feed system (such as transverse, longitudinal, or vertical feed) moves the workpiece between the grinding wheel and the worktable, ensuring uniform grinding of the workpiece surface.

(3) Grinding Process

During the grinding process, the cutting edge of the grinding wheel scrapes the workpiece surface, removing tiny metal particles through physical friction. Grinding methods can include fine grinding, rough grinding, or ultra-fine grinding, selected according to the surface roughness requirements and material properties of the workpiece.

(4) Cooling with Cutting Fluid

During the grinding process, the high-speed cutting can cause the temperature of the grinding wheel and workpiece surface to rise. Cutting fluid is used for cooling and lubrication. Cutting fluid helps reduce friction, lower temperature, and also helps remove grinding debris, maintaining the workpiece surface quality.

(5) Precision Control

Precision surface grinders are typically equipped with a CNC system or a precision manual adjustment device to control the feed rate, grinding depth, and wheel position, thereby ensuring that the workpiece's dimensions, flatness, and surface roughness meet requirements.

2. Advantages and Features of Precision Surface Grinding Machines

(1) High-Precision Machining

Precision surface grinders can achieve micron-level machining accuracy, making them particularly suitable for machining parts with extremely high requirements for dimensions, flatness, and surface finish. A high-precision feed system and stable wheel rotation ensure repeatability and consistency in machining.

(2) Excellent Surface Quality

Through precision grinding, workpiece surfaces achieve extremely smooth surfaces, typically with low surface roughness. Precision surface grinders are widely used in machining workpieces requiring high surface finish, such as mold surfaces, optical lenses, and precision instrument parts.

(3) Strong Applicability

Precision surface grinders are not only suitable for metallic materials but can also process non-metallic materials such as plastics and ceramics. Their strong adaptability allows them to handle workpieces of different hardness and materials, making them widely used in industries such as machinery, electronics, automotive, and aerospace.

(4) High-efficiency machining

During precision grinding, precision surface grinders can remove a large amount of material in a short time, making them more efficient than traditional machining methods. Especially in mass production, precision surface grinders can guarantee high-quality and high-efficiency machining.

(5) High structural stability and rigidity

Precision surface grinders adopt a high-rigidity frame structure, capable of withstanding large cutting forces and maintaining machine stability, reducing vibration, and ensuring machining accuracy. At the same time, the guideways and spindle system of the grinder are also precisely designed to ensure long-term accuracy maintenance.

3. Key Maintenance Points for Precision Surface Grinding Machines

To ensure the long-term stable operation and high precision of a precision surface grinder, regular maintenance is essential. The following are the main maintenance points for precision surface grinders:

Cleanliness and lubrication are fundamental to maintaining the normal operation of a precision surface grinder. After each day's use, it is necessary to remove grinding debris, cutting fluid, and other contaminants from the grinder surface, guideways, and grinding wheel. Especially in areas such as the guideways and lead screw, regularly add appropriate lubricating oil to prevent wear and corrosion.

The grinding wheel is one of the most important components of a precision surface grinder. Regularly check the wear condition of the grinding wheel to ensure that its surface is not excessively worn or unevenly worn. For severely worn grinding wheels, they should be replaced or overhauled promptly to avoid affecting machining accuracy and surface quality.

With prolonged use, the machining accuracy of a precision surface grinder may deviate, therefore, regular accuracy calibration is necessary. Use high-precision measuring tools (such as optical levels, measuring instruments, etc.) to check the flatness, perpendicularity, and accuracy of the machine tool, and make adjustments as necessary.

Emergency handling for sudden malfunctions:

| Fault Symptoms | Temporary Measures | Follow-up Handling |

| Grinding Surface Vibration Marks | Immediately stop the machine and check the grinding wheel balance and spindle bearing clearance. | Contact the manufacturer to replace the bearing (replace if clearance > 0.003mm). |

| Hydraulic System Pressure Fluctuations | Switch to the spare filter and replenish with the same type of hydraulic oil. | Clean the relief valve and check the swashplate angle of the variable pump. |

русский

русский عربى

عربى