-

How to Maintain an EDM Machine Properly? -2026 -02-27Proper EDM Machine Maintenance Extends Lifespan and Precision The most effective way to maintain an EDM Machine is through consistent preventive maintenance—regular dielectric fluid management, electrode system inspection, electrical component checks, and strict cleanliness control. When maintained properly, an EDM Ma...

-

Why Engraving and Milling Machines Are a Game Changer for Manufacturing? -2026 -02-20Why Engraving and Milling Machines Are a Game Changer for Manufacturing Engraving and milling machines are essential tools in modern manufacturing, offering precision, versatility, and efficiency in creating detailed designs and complex shapes. These machines are used in various industries, from automotive and aerospa...

-

CNC EDM Die Sinking Machine: Is It the Best Choice for Precision Mold Making? -2026 -02-13Is a CNC EDM Die Sinking Machine the Best Solution for High-Precision Mold Manufacturing? The short answer is yes. A CNC EDM Die Sinking Machine is one of the most reliable solutions for producing complex cavities, sharp internal corners, and ultra-precise mold details that traditional machining cannot achieve. With p...

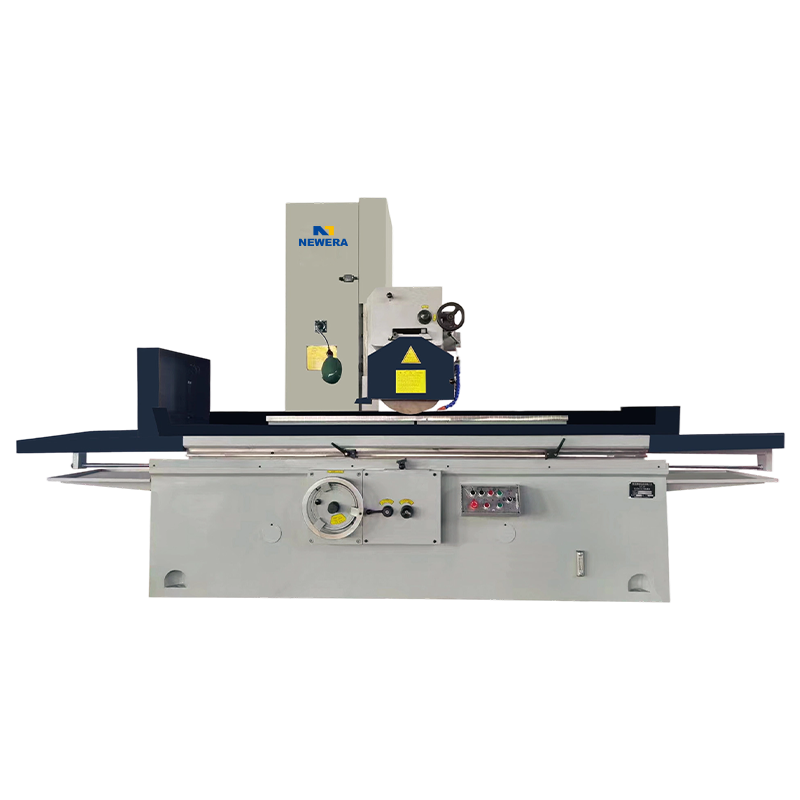

Horizontal Shaft Rectangular Table Surface Grinding Machine Manufacturers

As a professional OEM Horizontal Shaft Rectangular Table Surface Grinding Machine Manufacturers and ODM Horizontal Shaft Rectangular Table Surface Grinding Machine Factory, New Era has continuously obtained the advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and mounting center.We always provide customers with the best solutions and creates the maximum value with high-quality products and perfect services.

A horizontal shaft rectangular table surface grinder is a machine tool used for precision grinding of workpiece surfaces. It has a wide range of applications, especially in machining parts requiring high precision and high surface finish. Its key feature is its horizontal layout design, which gives the machine higher rigidity, more stable machining performance, and the ability to accommodate larger workpieces.

As a professional OEM manufacturer and ODM manufacturer of horizontal shaft rectangular table surface grinders, New Era has continuously achieved advanced scientific and technological achievements both domestically and internationally, and has now developed into a professional manufacturer with a complete production and installation center.

1. Working Principle of Horizontal Shaft Rectangular Table Surface Grinding Machine

The working principle of a horizontal shaft rectangular table surface grinder is similar to other surface grinders. Grinding is performed by the grinding wheel on the grinder contacting the workpiece surface. The main working process can be divided into the following steps:

(1) Workpiece Fixing

The workpiece is fixed to the worktable using a magnetic chuck, clamp, or a dedicated fixing device. The worktable is rectangular in shape and moves along a horizontal axis (lateral) or a vertical axis (longitudinal) to ensure that the workpiece does not shift during grinding. The rectangular worktable design allows the machine tool to carry larger and heavier workpieces, making it suitable for precision grinding of large workpieces.

(2) Grinding Wheel Rotation and Grinding

The grinding machine spindle drives the grinding wheel to rotate, and grinding begins after the grinding wheel contacts the workpiece surface. The rotational speed of the grinding wheel is coordinated with the feed speed of the workpiece, and the tiny particles on the workpiece surface are removed through physical friction, gradually achieving a smooth and even surface. During the grinding process, the grinding machine adjusts the movement trajectory of the workpiece or grinding wheel through the transverse, longitudinal, or vertical feed control system to ensure uniform grinding of the workpiece surface.

(3) Cooling and Chip Removal

Because the grinding process generates high temperatures, the cutting fluid system plays a role in cooling and lubrication during the grinding process. Cutting fluid not only reduces friction and temperature during grinding but also helps clean grinding debris from the workpiece surface, preventing it from affecting machining accuracy.

(4) Precision Control

Horizontal axis rectangular table surface grinders are typically equipped with a CNC system or manual adjustment device, which can precisely control machining parameters such as grinding depth, feed rate, and workpiece position to ensure workpiece accuracy and surface quality.

2. Features of Horizontal Shaft Rectangular Table Surface Grinding Machine

(1) High Rigidity and Stability

The horizontal structure design of the horizontal shaft rectangular table surface grinder provides stronger rigidity, enabling it to withstand larger cutting forces and maintain less deformation during grinding. The rectangular design of the table ensures a larger support surface, making the processing of heavier or larger workpieces more stable.

(2) Adaptability to Large-Size Workpiece Processing

Compared to vertical surface grinders, the horizontal shaft rectangular table surface grinder has a larger table, capable of supporting larger workpieces, making it suitable for processing large parts, such as molds, machine tool beds, and large mechanical parts. Its larger processing range makes it an ideal device for heavy machinery and mold manufacturing.

(3) Excellent Machining Accuracy

Through a precise CNC system or manual adjustment device, the horizontal shaft rectangular table surface grinder can achieve micron-level machining accuracy. Its high rigidity and precision control system ensure that the surface flatness and smoothness of the workpiece meet the stringent requirements, making it widely used in machining tasks requiring high precision.

(4) Multifunctionality and Flexibility

The horizontal axis rectangular table surface grinder can not only perform ordinary surface grinding, but also grinding inclined surfaces, stepped surfaces, and irregularly shaped surfaces. Its flexible machining methods adapt to the machining needs of various workpieces, increasing the machine tool's application range.

(5) Reduced Vibration and Improved Machining Quality

The horizontal design reduces vibration problems caused by unstable center of gravity, which may occur with vertical grinders, ensuring a smoother grinding process, thereby improving machining accuracy and surface finish.

2. Features of Horizontal Shaft Rectangular Table Surface Grinding Machine

(1) High Rigidity and Stability

The horizontal structure design of the horizontal shaft rectangular table surface grinder provides stronger rigidity, enabling it to withstand larger cutting forces and maintain less deformation during grinding. The rectangular design of the table ensures a larger support surface, making the processing of heavier or larger workpieces more stable.

(2) Adaptability to Large-Size Workpiece Processing

Compared to vertical surface grinders, the horizontal shaft rectangular table surface grinder has a larger table, capable of supporting larger workpieces, making it suitable for processing large parts, such as molds, machine tool beds, and large mechanical parts. Its larger processing range makes it an ideal device for heavy machinery and mold manufacturing.

(3) Excellent Machining Accuracy

Through a precise CNC system or manual adjustment device, the horizontal shaft rectangular table surface grinder can achieve micron-level machining accuracy. Its high rigidity and precision control system ensure that the surface flatness and smoothness of the workpiece meet the stringent requirements, making it widely used in machining tasks requiring high precision.

(4) Multifunctionality and Flexibility

The horizontal axis rectangular table surface grinder can not only perform ordinary surface grinding, but also grinding inclined surfaces, stepped surfaces, and irregularly shaped surfaces. Its flexible machining methods adapt to the machining needs of various workpieces, increasing the machine tool's application range.

(5) Reduced Vibration and Improved Machining Quality

The horizontal design reduces vibration problems caused by unstable center of gravity, which may occur with vertical grinders, ensuring a smoother grinding process, thereby improving machining accuracy and surface finish.

3. Maintenance Points of Horizontal Axis Rectangular Table Surface Grinding Machine

To ensure the long-term stable operation of the horizontal axis rectangular table surface grinding machine and maintain its high-precision machining capabilities, regular maintenance is essential. The following are some key maintenance points:

(1) Regular Cleaning and Lubrication

The surface of the grinding machine, guide rails, grinding wheels, and other parts need to be cleaned regularly to prevent dust and cutting chips from accumulating inside the machine and affecting its accuracy. In particular, guide rails and lead screws should be regularly lubricated to prevent wear and maintain smooth movement.

(2) Checking and Dressing the Grinding Wheel

The degree of wear on the grinding wheel directly affects machining accuracy and surface quality. The wear of the grinding wheel should be checked regularly to ensure even wear, and it should be dressed or replaced if necessary. Regularly dressing the grinding wheel can maintain its optimal cutting condition and prevent uneven workpiece surface or accuracy errors due to grinding wheel problems.

(3) Calibrating the Machine Tool's Accuracy

After prolonged use, the machine tool may experience accuracy deviations, therefore, it needs to be calibrated regularly. Use precision measuring tools to check the flatness, perpendicularity, and table movement accuracy of the machine tool to ensure that the workpiece accuracy is not affected during processing.

(4) Spindle and Drive System Inspection

The spindle and drive system are the core components of a horizontal-axis rectangular table surface grinder. Regularly check the spindle for smooth operation and the drive system for abnormal noise or vibration. If any abnormalities are found, repair or replacement should be carried out immediately.

(5) Coolant and Chip Removal System Maintenance

The coolant system needs regular checks of level and quality to prevent contamination or unsuitable concentration, which could affect cooling performance. The chip removal system also needs regular cleaning to ensure that chips do not accumulate on the table or grinding wheel, affecting machining accuracy.

(6) Electrical System Inspection

The stability of the electrical system directly affects the normal operation of the grinder. Regularly check electrical components, control panels, and cable connections to ensure that all electrical components are not loose or aged, avoiding machining interruptions due to electrical faults.

(7) Environmental Management

Precision grinders have high environmental requirements, needing to maintain constant temperature and humidity. Excessive temperature differences can cause thermal expansion of the machine tool, affecting machining accuracy. Therefore, it is recommended to install the machine tool in a temperature-controlled workshop to avoid the impact of high temperature and humidity on machine tool performance.

русский

русский عربى

عربى