-

How to Maintain an EDM Machine Properly? -2026 -02-27Proper EDM Machine Maintenance Extends Lifespan and Precision The most effective way to maintain an EDM Machine is through consistent preventive maintenance—regular dielectric fluid management, electrode system inspection, electrical component checks, and strict cleanliness control. When maintained properly, an EDM Ma...

-

Why Engraving and Milling Machines Are a Game Changer for Manufacturing? -2026 -02-20Why Engraving and Milling Machines Are a Game Changer for Manufacturing Engraving and milling machines are essential tools in modern manufacturing, offering precision, versatility, and efficiency in creating detailed designs and complex shapes. These machines are used in various industries, from automotive and aerospa...

-

CNC EDM Die Sinking Machine: Is It the Best Choice for Precision Mold Making? -2026 -02-13Is a CNC EDM Die Sinking Machine the Best Solution for High-Precision Mold Manufacturing? The short answer is yes. A CNC EDM Die Sinking Machine is one of the most reliable solutions for producing complex cavities, sharp internal corners, and ultra-precise mold details that traditional machining cannot achieve. With p...

Grinding Machine Suppliers

A grinding machine, or grinder, is a power tool that uses an abrasive wheel to remove material from a workpiece's surface. It is designed for achieving extremely high dimensional accuracy and superior surface finish, which is often unattainable by other machining processes like milling or turning. It is essential for finishing parts to precise tolerances.

-

-

-

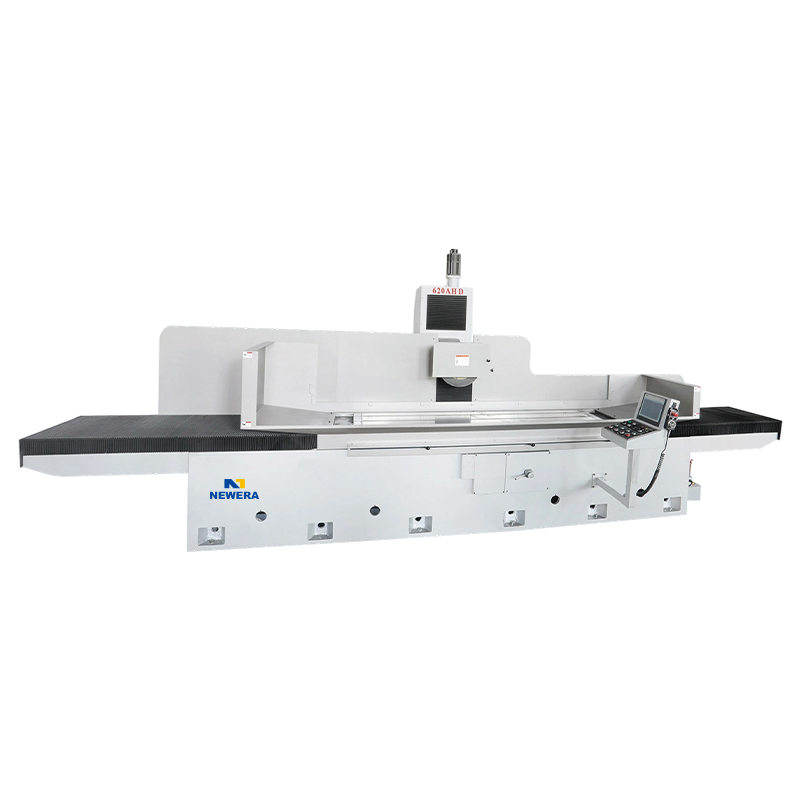

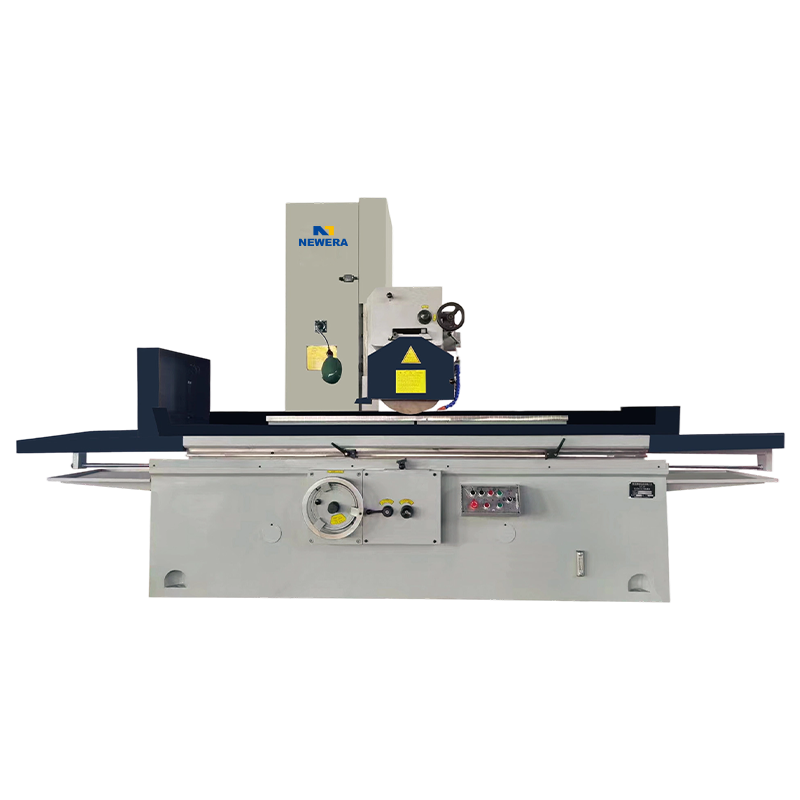

M7132/7140/7150/7163/7180-16 Horizontal Shaft Rectangular Table Surface Grinding Machine

-

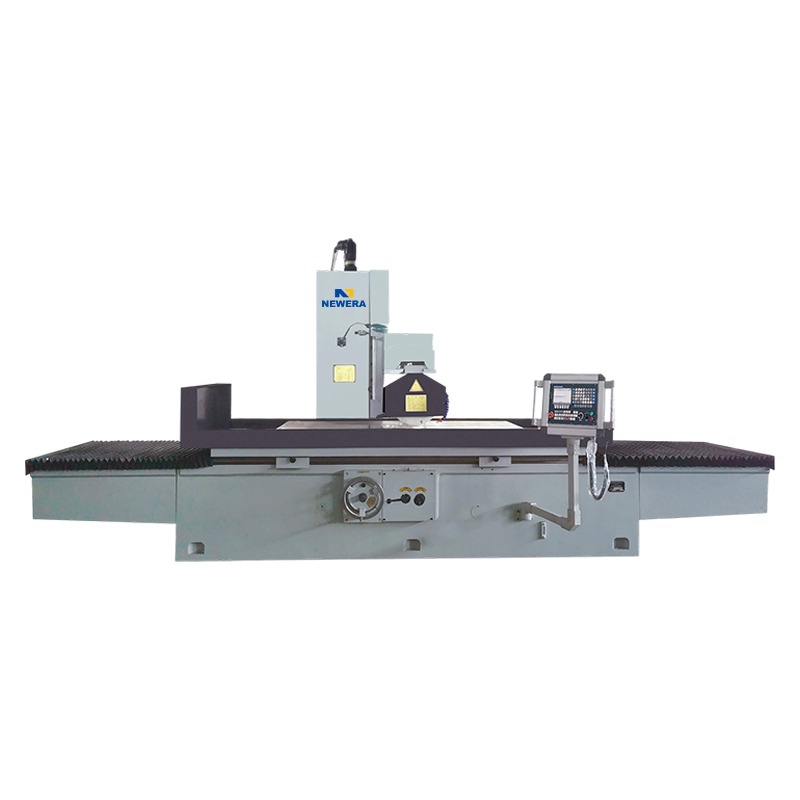

CKM7140/7150/7163/7180 Program Controlled Surface Grinding Machine

As a professional OEM Grinding Machine Suppliers and ODM Grinding Machine Company, New Era has continuously obtained the advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and mounting center.We always provide customers with the best solutions and creates the maximum value with high-quality products and perfect services.

A grinding machine is a machine tool that uses the cutting action of abrasive grains to process the surface of a workpiece. Grinding, as a high-precision machining method with high surface quality, is widely used in machinery manufacturing, the automotive industry, aerospace, and tool manufacturing. Grinding machines can precisely machine complex surfaces of workpieces, achieving high surface finish and low surface roughness, making them an important tool in precision machining.

The working principle of a grinding machine is to use a high-speed rotating grinding wheel to contact the workpiece surface, removing excess material through the cutting action of the abrasive grains to achieve the desired shape and size. Depending on the workpiece requirements, grinding machines can perform various grinding methods, including surface grinding, cylindrical grinding, internal grinding, and centerless grinding.

1. Main Types of Grinding Machines

Surface Grinding Machines:

Surface grinding machines are the most common type of grinding machine, mainly used for machining the flat surfaces of workpieces. By fixing the workpiece and using a rotating grinding wheel, they can achieve very high flatness and surface finish. Surface grinding machines are often used for mass production or surface machining of small, single parts.

External Cylindrical Grinding Machine:

External cylindrical grinding machines are used to grind the outer cylindrical surfaces of workpieces. They are suitable for workpieces with cylindrical surfaces, such as shafts and discs. The working principle typically involves fixing the workpiece in a fixture and grinding its outer surface using grinding wheels.

Internal Cylindrical Grinding Machine:

Internal cylindrical grinding machines are used to machine the inner cylindrical surfaces of workpieces, such as internal holes and grooves. Their working principle is similar to that of external cylindrical grinding machines, except that they grind the inner surface of the workpiece. Internal cylindrical grinding machines are widely used in the machining of precision parts and automotive and aerospace components.

Centerless Grinding Machine:

Centerless grinding machines are mainly used to machine the outer cylindrical surfaces of long shaft parts. They do not require workpiece clamping; the feed and position of the workpiece are controlled solely by two grinding wheels. Centerless grinding machines are characterized by high efficiency and high precision, making them suitable for mass production of similar parts.

Tool Grinding Machine:

Tool grinding machines are mainly used to machine the cutting parts of various tools, such as drills, milling cutters, and cutting tools. They can precisely grind the cutting edges of tools, ensuring their cutting performance. Tool grinders can not only perform precision grinding on workpieces, but also adjust and optimize their shapes in multiple directions.

2. Working Principle of Grinding Machines

The basic working principle of a grinding machine is that a high-speed rotating grinding wheel (i.e., abrasive) contacts the workpiece surface, using the cutting action of the abrasive grains to remove material from the workpiece surface. During grinding, the abrasive grains have tiny cutting edges, generating cutting force through friction with the workpiece surface, removing material from the workpiece surface, thereby achieving precise dimensions and surface quality requirements.

The motion of a grinding machine is divided into three main forms: the rotational motion of the grinding wheel, the feed motion of the workpiece, and the rotational motion of the workpiece. The rotation of the grinding wheel is the main power source for grinding, while the feed motion and rotation of the workpiece help to achieve uniform grinding, avoid excessive local wear, and thus ensure the consistency of the machined surface.

3. Application Areas of Grinding Machines

Grinding machines have a wide range of applications, covering almost all processing fields requiring high precision and surface finish:

(1) Mechanical Manufacturing: The main applications of grinding machines in mechanical manufacturing include processing various precision parts, such as shafts, gears, pump bodies, etc. These components have strict requirements for size and surface quality, and grinding machines can provide stable and high-precision machining results.

(2) Automotive Industry: In the automotive industry, grinding machines are commonly used to process engine parts, transmission parts, brake discs, wheels, etc. These components require good surface quality and dimensional accuracy, and grinding machines can ensure their machining performance and reliability.

(3) Aerospace: The aerospace industry has very high requirements for the precision and surface quality of parts. Grinding machines can be used to process key components of aero engines, structural parts, missile components, etc.

(4) Tool Manufacturing: Grinding machines play an important role in the manufacturing of cutting tools and tools. They can precisely grind the cutting edges of cutting tools, improving the cutting efficiency and service life of tools.

(5) Mold Manufacturing: Grinding machines are commonly used for mold processing, especially for grinding high-precision molds and complex-shaped molds. Through grinding machines, the surface quality of molds can reach very high standards, ensuring the quality of the final product.

4. Grinding Machine Maintenance and Preventive Measures Table

| Maintenance Items | Specific Operations | Frequency | Precautions |

| Grinding Wheel Maintenance | Check the grinding wheel's balance and perform a dynamic balancing test after installation; clean surface shavings. | When Replacing Grinding Wheels | Avoid using cracked or expired grinding wheels; the rotation direction must be consistent with the markings |

| Lubrication System | Check the lubricating oil level in guideways, lead screws, and bearings; replenish or replace with the specified type of lubricating oil. | Weekly/Every 50 Hours | Use manufacturer-recommended oil; avoid mixing different types of grease. |

| Coolant Management | Clean the coolant tank of impurities; check the concentration (usually 5%~10%); replenish or replace any excess coolant. | Weekly | Prevent coolant corrosion (add bactericide if necessary); filter metal debris. |

| Hydraulic System | Check hydraulic oil level and pressure; clean or replace the filter element; observe for leaks. | Monthly | Ensure oil temperature does not exceed 60℃; completely change the oil if foaming or turbidity is observed. |

| Precision Calibration | Test grinding accuracy (e.g., parallelism, roundness) using standard test pieces; adjust machine tool geometry parameters. | Quarterly | Perform calibration when the ambient temperature is stable; record calibration data for future reference. |

Nantong New Era Technology Co., Ltd. is a professional enterprise specializing in the research, design, and production of grinding machines. We have a professional team integrating technology research and development, manufacturing, and sales services. As a professional OEM grinding machine manufacturer, New Era continuously achieves advanced technological results both domestically and internationally, and has now developed into a professional manufacturer with a complete production and installation center.

Grinding machines, as important equipment in precision machining, play an irreplaceable role in the manufacturing industry. They can not only perform high-precision parts machining but also provide extremely high surface quality, meeting the precision machining needs of various industries.

русский

русский عربى

عربى