-

How to Maintain an EDM Machine Properly? -2026 -02-27Proper EDM Machine Maintenance Extends Lifespan and Precision The most effective way to maintain an EDM Machine is through consistent preventive maintenance—regular dielectric fluid management, electrode system inspection, electrical component checks, and strict cleanliness control. When maintained properly, an EDM Ma...

-

Why Engraving and Milling Machines Are a Game Changer for Manufacturing? -2026 -02-20Why Engraving and Milling Machines Are a Game Changer for Manufacturing Engraving and milling machines are essential tools in modern manufacturing, offering precision, versatility, and efficiency in creating detailed designs and complex shapes. These machines are used in various industries, from automotive and aerospa...

-

CNC EDM Die Sinking Machine: Is It the Best Choice for Precision Mold Making? -2026 -02-13Is a CNC EDM Die Sinking Machine the Best Solution for High-Precision Mold Manufacturing? The short answer is yes. A CNC EDM Die Sinking Machine is one of the most reliable solutions for producing complex cavities, sharp internal corners, and ultra-precise mold details that traditional machining cannot achieve. With p...

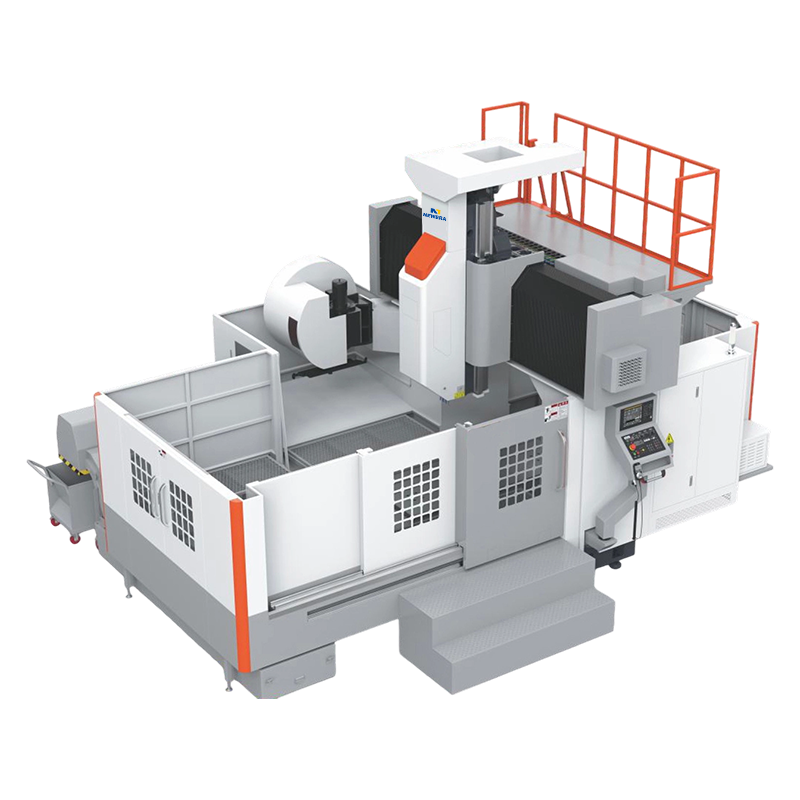

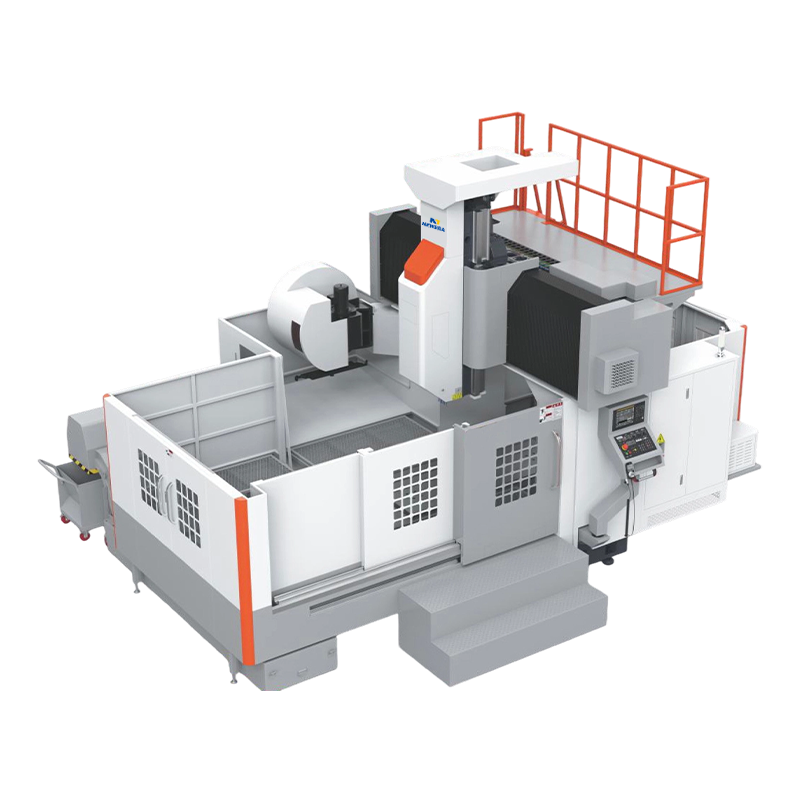

Gantry Machining Center Suppliers

The gantry machining center, or gantry milling machine, shares the same core functionality as a conventional milling machine. A gantry machining center is a CNC bridge-like mill for large parts. Its key distinction from a traditional gantry milling machine is its integrated automatic tool changer (ATC), which enables automated, uninterrupted production.

As a professional OEM Gantry Machining Center Suppliers and ODM Gantry Machining Center Factory, New Era has continuously obtained the advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and mounting center.We always provide customers with the best solutions and creates the maximum value with high-quality products and perfect services.

A gantry machining center is a CNC machine tool with a gantry-type structure, widely used for machining large and heavy workpieces. Its design features give it high rigidity and stability, making it particularly suitable for machining tasks requiring high precision and heavy loads, such as in aerospace, shipbuilding, mold making, and machinery manufacturing. Compared to traditional vertical or horizontal machining centers, gantry machining centers can withstand greater cutting forces, have a larger machining range, and higher production efficiency.

1. Basic Structure and Working Principle of Gantry Machining Centers

The bed of a gantry machining center adopts a "gantry"-shaped structure. The spindle head spans the workpiece through columns on both sides, forming a large-span machining area. This structure allows the machine tool to perform efficient machining on a large worktable, especially suitable for machining large, heavy workpieces. Its working principle is similar to that of conventional CNC machine tools, using a CNC system to control the precise movement of each axis to complete various operations such as milling, drilling, and tapping.

Gantry machining centers typically feature high-precision servo motors and linear guideways on their spindles and worktables, providing smooth and precise motion. Simultaneously, automatic tool changers enable automatic tool changes, improving production efficiency and reducing manual intervention.

2. Main Features of Gantry Machining Centers

(1) High Rigidity and Stability: Due to their gantry structure, gantry machining centers can withstand large cutting forces and loads, maintaining high precision even under high loads, making them suitable for heavy cutting and machining large workpieces.

(2) Large Machining Range: Due to their structural design, gantry machining centers are typically equipped with large worktables, enabling the machining of large workpieces, making them suitable for precision machining of large parts.

(3) High Precision Machining: The high rigidity design of gantry machining centers allows them to provide very high machining accuracy during complex and precision machining, performing particularly well in the machining of precision molds and aerospace parts.

(4) High Degree of Automation: Gantry machining centers are typically equipped with automatic tool changers, which can automatically switch between different tools, improving production efficiency and adapting to batch production and complex process requirements.

(5) Multi-axis Machining: Modern gantry machining centers support multi-axis machining, enabling simultaneous machining in multiple axes such as X, Y, and Z, meeting the machining needs of various complex parts.

3. Application Areas of Gantry Machining Centers

Mold Manufacturing: Gantry machining centers are suitable for machining various types of large molds, especially advantageous in mold manufacturing requiring precision hole machining and complex surface treatment.

Aerospace: Due to their large machining range and high-precision machining capabilities, gantry machining centers are widely used in the machining of aerospace components, such as aircraft frames and engine parts.

Shipbuilding: Ship parts are typically large and complex; gantry machining centers can handle large, heavy workpieces, meeting the machining needs of the shipbuilding industry.

Machinery Manufacturing: Gantry machining centers are widely used for machining large mechanical components, such as machine tool beds, supports, and frames.

Automotive Manufacturing: In the automotive industry, gantry machining centers can be used to machine large automotive parts, such as engine parts and body frames.

4. Common Faults and Solutions for Gantry Machining Centers

While gantry machining centers offer significant advantages in machining accuracy and capacity, their complex structure and high workload make them prone to malfunctions. Below are some common faults that may be encountered during the use of gantry machining centers and their solutions.

| Fault Type | Common Symptoms | Possible Causes | Solutions |

| Mechanical Transmission Fault | Decreased machining accuracy, abnormal noise, vibration | Guide rail/lead screw wear, poor lubrication, damaged bearings | Clean and re-lubricate the guide rail/lead screw; replace damaged bearings; adjust the clearance of transmission components. |

| Spindle Fault | Spindle overheating, unstable speed, excessive vibration | Spindle bearing wear, tool imbalance, insufficient cooling | Replace bearings; rebalance tools; check the spindle cooling system (e.g., water pump, piping). |

| Servo System Alarm | Driver alarm (e.g., overload, encoder error) | Motor overload, loose encoder cable, incorrect parameter settings | Check if the load is too high; reconnect the encoder cable; restore the servo driver to default parameters and recalibrate. |

| Tool Changer Fault | Tool changer jamming, tool drop, tool magazine not rotating | Insufficient air pressure, tool magazine motor failure, sensor malfunction | Check air source pressure (≥0.5MPa); clean or replace sensors; manually reset the tool magazine and recalibrate. |

Gantry machining centers are highly efficient and precise machining equipment suitable for processing large-size, high-precision, and high-load workpieces. They are widely used in aerospace, mold making, shipbuilding, and automotive industries.

Nantong New Era Technology Co., Ltd. is a professional enterprise specializing in the R&D, design, and production of gantry machining centers. We have a professional team integrating technology R&D, manufacturing, and sales services. As a professional OEM gantry machining center supplier and ODM gantry machining center manufacturer, New Era continuously achieves advanced technological results both domestically and internationally, and has now developed into a professional manufacturer with a complete production and installation center.

русский

русский عربى

عربى