-

How to Maintain an EDM Machine Properly? -2026 -02-27Proper EDM Machine Maintenance Extends Lifespan and Precision The most effective way to maintain an EDM Machine is through consistent preventive maintenance—regular dielectric fluid management, electrode system inspection, electrical component checks, and strict cleanliness control. When maintained properly, an EDM Ma...

-

Why Engraving and Milling Machines Are a Game Changer for Manufacturing? -2026 -02-20Why Engraving and Milling Machines Are a Game Changer for Manufacturing Engraving and milling machines are essential tools in modern manufacturing, offering precision, versatility, and efficiency in creating detailed designs and complex shapes. These machines are used in various industries, from automotive and aerospa...

-

CNC EDM Die Sinking Machine: Is It the Best Choice for Precision Mold Making? -2026 -02-13Is a CNC EDM Die Sinking Machine the Best Solution for High-Precision Mold Manufacturing? The short answer is yes. A CNC EDM Die Sinking Machine is one of the most reliable solutions for producing complex cavities, sharp internal corners, and ultra-precise mold details that traditional machining cannot achieve. With p...

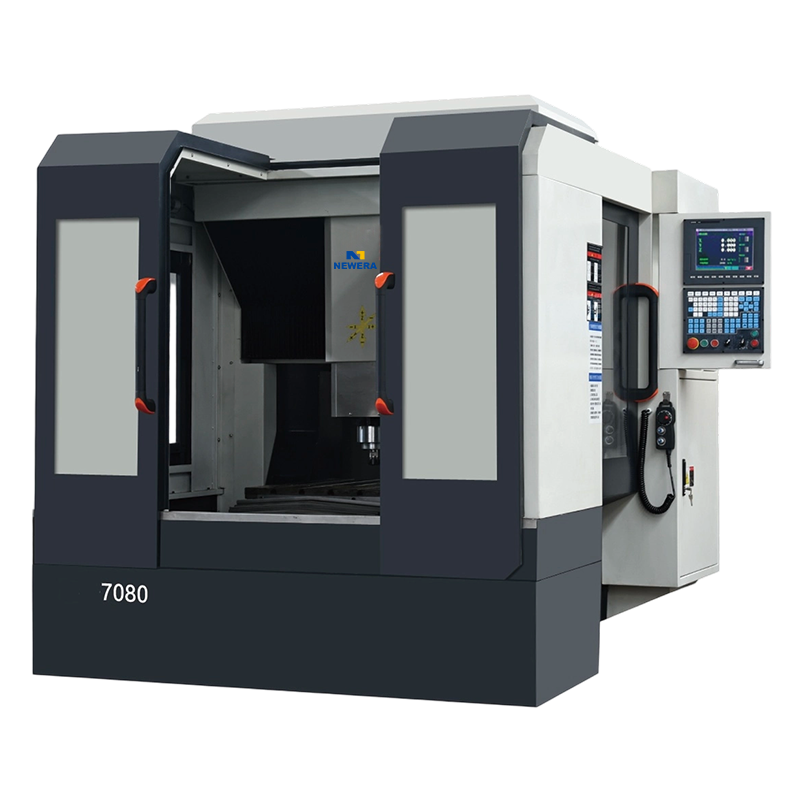

As a professional OEM CNC Engraving and Milling Machine Manufacturers and ODM CNC Engraving and Milling Machine Factory, New Era has continuously obtained the advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and mounting center.We always provide customers with the best solutions and creates the maximum value with high-quality products and perfect services.

A CNC engraving and milling machine is a CNC machine tool that integrates engraving and milling, widely used for engraving and precision machining of materials such as wood, stone, metal, and plastics. Through precise control of the cutting tool by a CNC system, it achieves the engraving and machining of complex patterns, text, shapes, and various fine crafts. Due to its high precision, high efficiency, and strong machining capabilities, CNC engraving and milling machines are widely used in many industries, especially in mold making, advertising production, art engraving, and furniture processing.

1. Definition of CNC Engraving and Milling Machine

A CNC engraving and milling machine is a machine tool with a computer numerical control system as its core control component, mainly used for processing complex engraved patterns and parts. It combines the characteristics of traditional milling machines and engraving machines, enabling fine cutting, engraving, and milling operations. By precisely controlling the movement trajectory of the cutting tool, CNC engraving and milling machines achieve high-precision engraving and machining, suitable for processing various complex parts, molds, and works of art.

As a professional OEM CNC Engraving and Milling Machine Manufacturer and ODM CNC Engraving and Milling Machine Factory, New Era has continuously achieved advanced scientific and technological achievements both domestically and internationally, and has now developed into a professional manufacturer with a complete production and installation center.

2. Advantages and Features of CNC Engraving and Milling Machines

(1) High-Precision Machining

CNC engraving and milling machines use a CNC system to precisely control the tool path and feed rate, achieving micron-level machining accuracy. They can accurately engrave complex patterns, text, curved surfaces, etc., and can easily complete even very delicate process requirements.

(2) High Efficiency

Due to the high machining efficiency of CNC engraving and milling machines, they can complete a large number of engraving and milling tasks in a short time. Especially in situations requiring mass production, CNC engraving and milling machines can significantly improve production efficiency and shorten the production cycle.

(3) Three-Dimensional Engraving Capability

CNC engraving and milling machines can not only perform two-dimensional planar engraving, but also three-dimensional engraving. It can automatically plan toolpaths based on 3D models, enabling the engraving of complex surfaces and three-dimensional patterns, meeting the processing needs of various complex workpieces.

(4) Multi-material processing capability

CNC engraving milling machines are widely applicable to the processing of various materials, such as wood, stone, metal, and plastic. Depending on the material, CNC engraving milling machines can select different tools and cutting parameters to achieve the best processing results.

3. Cleaning points for CNC engraving milling machines

| Cleaning Area | Operating Procedures | Tools/Materials | Precautions | Recommended Cycle |

| Spindle and Tool | 1. Blow away debris from the spindle taper bore with an air gun (air pressure ≤ 0.2MPa). 2. Clean the tool holder contact surface with an alcohol swab. | • Low-pressure air gun • Non-woven cloth/alcohol swab | • Do not scrape the taper bore with metal tools. • Ensure the taper bore is dry before loading the tool. | After each tool change |

| Debris Residue in Engraving Area | 1. Clean residual debris from the bottom of the workpiece (especially for deep groove engraving). 2. Check for blockages in the cooling air nozzles. |

• Long, thin tweezers • Needle-tipped hole clearing tool |

• Tiny debris can cause machining errors. • Air-cooled equipment needs to be drained regularly. |

Every 2 hours or when changing materials |

| Appearance and Control Panel | 1. Wipe away oil stains on the body with a microfiber cloth. 2. Clean the crevices between the buttons with a soft-bristled brush. |

• Microfiber cloth • Keyboard cleaning adhesive | • Do not use alcohol to wipe the acrylic panel (it may crack). • Prevent liquid from seeping into the buttons. |

Daily |

| Waste Collection System | 1. Empty the dust bag (the bag filter needs to be tapped clean). 2. Check the suction pipe for damage. |

• Dust bag cleaner • Pipe inspection light |

• Fine dust can easily cause deflagration; anti-static treatment is required. • Replace the HEPA filter regularly. |

Every 8 hours (high-intensity use) |

русский

русский عربى

عربى