-

How to Maintain an EDM Machine Properly? -2026 -02-27Proper EDM Machine Maintenance Extends Lifespan and Precision The most effective way to maintain an EDM Machine is through consistent preventive maintenance—regular dielectric fluid management, electrode system inspection, electrical component checks, and strict cleanliness control. When maintained properly, an EDM Ma...

-

Why Engraving and Milling Machines Are a Game Changer for Manufacturing? -2026 -02-20Why Engraving and Milling Machines Are a Game Changer for Manufacturing Engraving and milling machines are essential tools in modern manufacturing, offering precision, versatility, and efficiency in creating detailed designs and complex shapes. These machines are used in various industries, from automotive and aerospa...

-

CNC EDM Die Sinking Machine: Is It the Best Choice for Precision Mold Making? -2026 -02-13Is a CNC EDM Die Sinking Machine the Best Solution for High-Precision Mold Manufacturing? The short answer is yes. A CNC EDM Die Sinking Machine is one of the most reliable solutions for producing complex cavities, sharp internal corners, and ultra-precise mold details that traditional machining cannot achieve. With p...

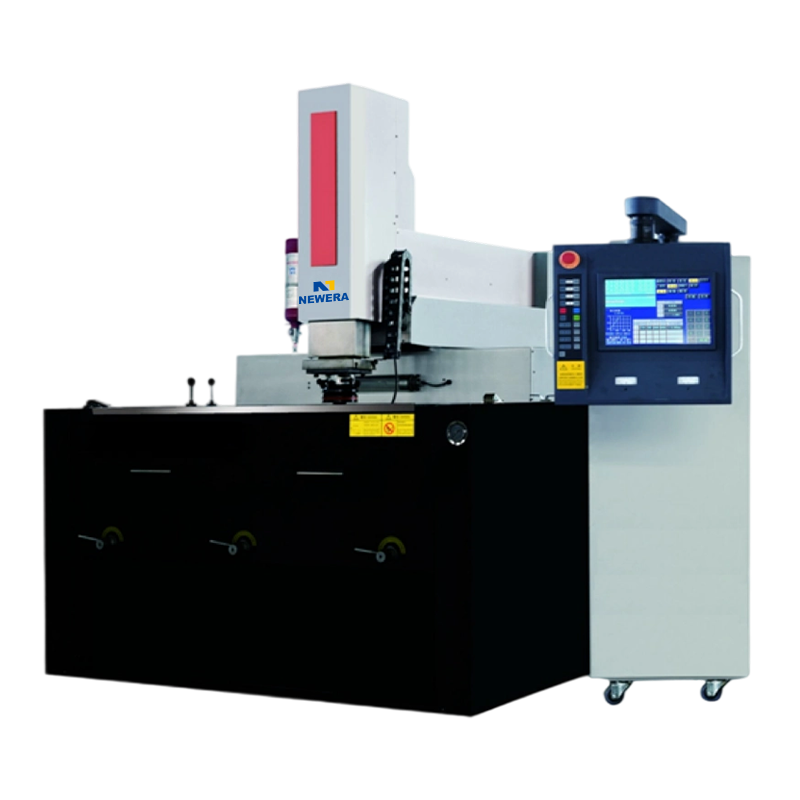

As a professional OEM CNC EDM Die Sinking Machine Suppliers and ODM CNC EDM machine Factory, New Era has continuously obtained the advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and mounting center.We always provide customers with the best solutions and creates the maximum value with high-quality products and perfect services.

A CNC electrical discharge machine (EDM) is a high-precision machining equipment based on the principle of electrical discharge. It generates high-frequency electrical sparks between the workpiece and the electrode, causing localized melting or vaporization of the workpiece surface, thereby achieving precise cutting, drilling, and forming operations. Due to its ability to process complex shapes and materials with high hardness, CNC electrical discharge machines are widely used in mold manufacturing, aerospace, automotive, and electronics industries.

As a professional OEM CNC EDM Die Sinking Machine Supplier and ODM CNC EDM machine Factory, New Era has continuously achieved advanced scientific and technological achievements at home and abroad, and has now developed into a professional manufacturer with a complete production and installation center.

1. Working Principle of CNC Electrical Discharge Machine

The core principle of a CNC electrical discharge machine is to remove material through electrical discharge. The specific process is as follows:

(1) Gap between electrode and workpiece: A certain gap is maintained between the electrode and the workpiece, usually at the micrometer level. The two are discharged through pulsed current, and each discharge generates high temperature and strong local melting effect.

(2) Electrical discharge: When the electric field strength between the electrode and the workpiece reaches a certain value, an electrical discharge occurs. The high temperature generated by each discharge locally melts the material on the surface of the workpiece, thereby achieving cutting and shaping.

(3) Material removal: Through continuous electrical discharge, the material on the surface of the workpiece is gradually removed, eventually achieving the desired processed shape.

(4) Relative movement between electrode and workpiece: The CNC electrical discharge forming machine uses a numerical control system to control the movement trajectory of the electrode, enabling the electrode to move precisely along a predetermined path, thereby achieving the processing of complex contours.

2. Main features of CNC electrical discharge forming machines

CNC electrical discharge forming machines have many unique advantages, making them irreplaceable in some traditional processing methods. The main features are as follows:

(1) High-precision processing: Electrical discharge forming machines can perform precision processing on extremely small scales, even processing micron-sized holes or complex geometric shapes. Its machining accuracy can typically reach ±0.002mm, making it suitable for machining molds and parts requiring extremely high precision.

(2) Machining hard and brittle materials: Unlike traditional machining, EDM machines can machine high-hardness materials such as cemented carbide, tool steel, and graphite, making them crucial in mold manufacturing and aerospace.

(3) Machining capability for complex shapes: EDM machines can machine complex shapes that are difficult to achieve with traditional cutting methods, such as internal cavities, deep holes, and micro-holes, making them particularly suitable for precision mold manufacturing.

(4) Non-contact machining: The EDM machining process does not rely on direct contact between the machine tool and the workpiece, thus avoiding physical interference caused by tool wear or workpiece surface issues, making it suitable for machining precision parts.

(5) High adaptability: EDM machines can machine on a variety of materials, including cemented carbide, hardened steel, and copper alloys, demonstrating strong adaptability to different materials. 3. CNC EDM Machine Cleaning Checklist

3. CNC Electrical Discharge Machining Machine Cleaning Guidelines

| Cleaning Items | Operating Procedures | Precautions | Recommended Cycle |

| Working Fluid Tank | 1. Drain the waste working fluid. 2. Wipe the inner wall for residual oil with a soft cloth or sponge. 3. Rinse and refill with new working fluid. |

• Avoid using corrosive cleaning agents. • Check the tank for leaks. |

Every 1-2 weeks or when changing the working fluid |

| Electrode and Workpiece Chuck | 1. Disassemble the electrode and wipe it with alcohol or a special cleaner. 2. Clean the oil and debris from the chuck contact surfaces. |

• Ensure the electrode is dry before installation. • Avoid scratching the contact surfaces. |

Daily or each time the electrode is changed |

| Worktable and Guide Rails | 1. Remove metal powder with a vacuum cleaner or soft brush. 2. Apply rust-preventive oil to protect the guide rails. |

• Do not use compressed air to blow directly (to avoid debris splashing). • Check the lubrication of the guide rails. |

Daily or per shift |

| Filter System | 1. Replace or clean the paper/metal filter. 2. Check for blockages in the lines. |

• Adjust the cycle according to the level of contamination in the working fluid. • Dispose of used filter cartridges according to environmental regulations. |

Weekly or according to pressure alarm notification |

| EDM Oil Tank | 1. Clean sediment from the bottom of the tank. 2. Check for blockages in the oil lines. |

• Use an oil filter to remove impurities. • Prevent water from entering. |

Monthly or when oil quality deteriorates |

CNC EDM machines, as a high-precision advanced machining equipment, are widely used in various industries such as mold manufacturing, aerospace, automotive, and electronics, thanks to their ability to process hard and brittle materials, complex shapes, and ultra-high precision. With continuous technological development, EDM machines will see further innovation in intelligence, automation, and environmental friendliness, and will undoubtedly play an even more important role in future manufacturing.

русский

русский عربى

عربى