-

-

-

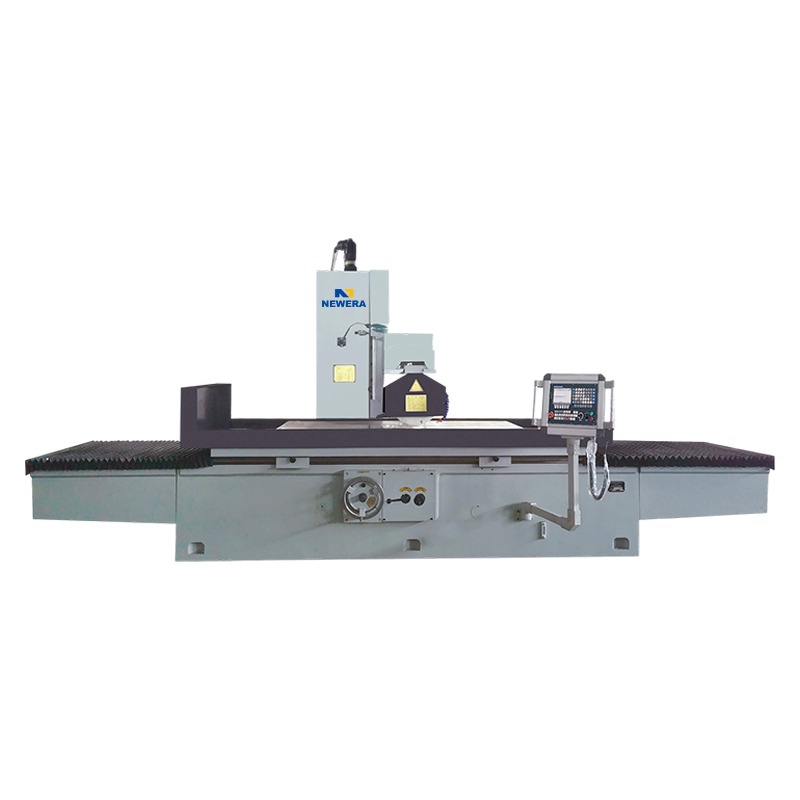

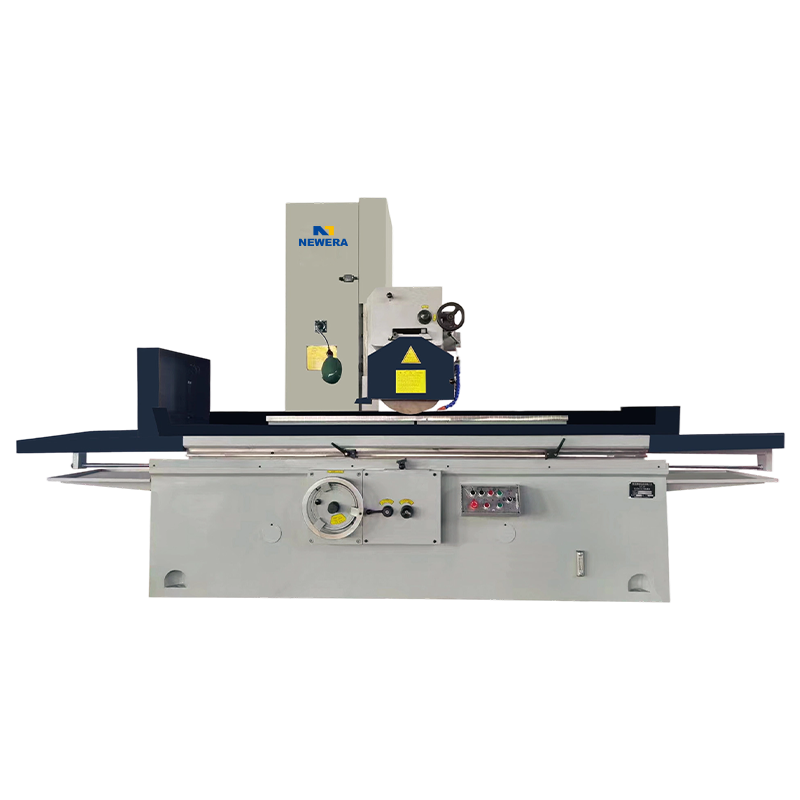

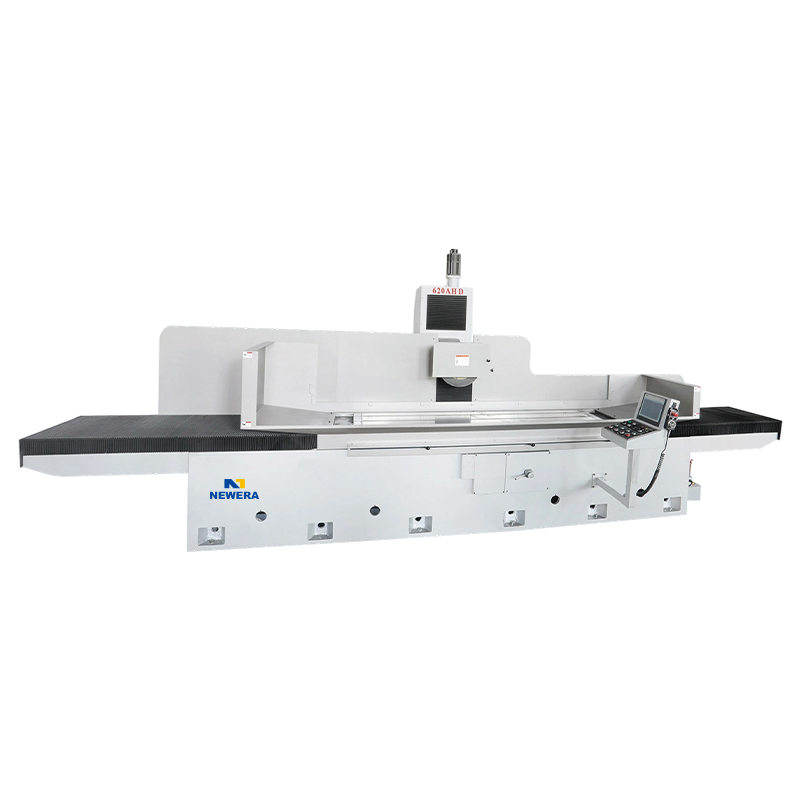

M7132/7140/7150/7163/7180-16 M7132/7140/7150/7163/7180-16 Horizontal Shaft Rectangular Table Surface Grinding Machine READ MORE

M7132/7140/7150/7163/7180-16 M7132/7140/7150/7163/7180-16 Horizontal Shaft Rectangular Table Surface Grinding Machine READ MORE -

-

-

-

-

-

-

-

-

What Are The Capabilities Of Sinker EDM

Here are the key capabilities that make Sinker EDM a vital technology:

Unmatched Complexity in Geometric Shapes: Sinker EDM excels at producing intricate geometries that are impossible with milling or turning. This includes internal sharp corners, deep ribs, complex 3D contours, fine details, and undercuts within a single setup. It is the ideal solution for molding cavities, forging dies, and aerospace components with demanding designs.

Machining Ultra-Hard Materials: Unlike conventional cutting tools that wear down quickly, Sinker EDM effortlessly machines hardened materials. This includes tool steels, carbide, Inconel, titanium, and other exotic alloys that have been pre-hardened. This eliminates the distortion risks associated with heat-treating a part after it has been machined.

Exceptional Surface Finish and Accuracy: The process achieves extremely fine surface finishes, often down to mirror-like qualities (Ra < 0.1 µm), reducing or eliminating the need for secondary polishing. It also holds exceptionally tight tolerances, routinely within microns (±0.005 mm or less), ensuring part-to-part consistency and perfection.

Burr-Free Production: Since material is removed by vaporization and melting rather than mechanical cutting, Sinker EDM produces absolutely no burrs. This results in clean, ready-to-use parts, saving significant time and cost on post-processing and deburring operations.

No Direct Mechanical Force: The workpiece and electrode never physically touch. This eliminates mechanical stresses, chatter, and vibration, making it possible to machine delicate, fragile, and thin-walled features without the risk of bending or breaking them.

Precise Micro-Machining: Modern Sinker EDM machines are capable of micro-scale machining, creating incredibly small holes, slots, and text with high precision. This is crucial for medical devices, micro-molds, and electronics components.

Automation and Repeatability: Modern CNC Sinker EDM systems allow for fully automated operation. They can run unattended for long periods, including automatic electrode changes and adaptive power settings, ensuring high-volume production with flawless repeatability.

русский

русский عربى

عربى