What are the key points for the maintenance and upkeep of a graphite engraving and milling machine?

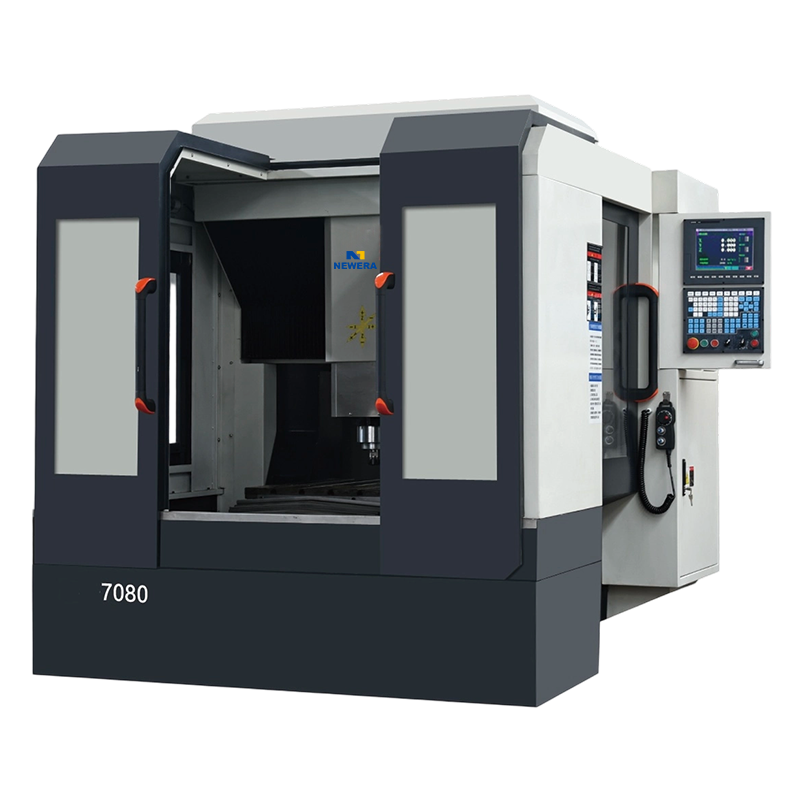

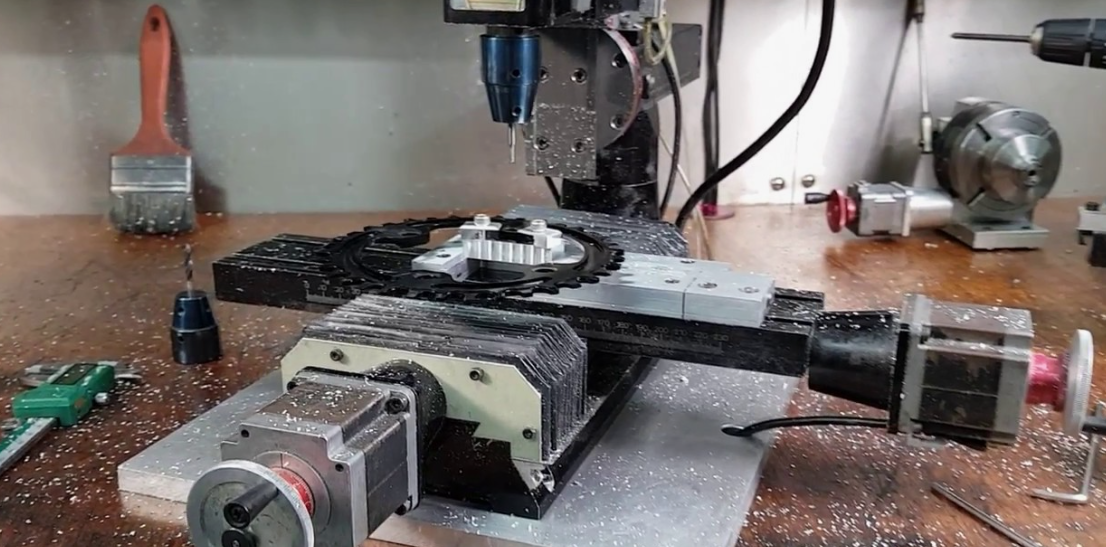

Graphite engraving and milling machines are specialized equipment used for high-precision processing of graphite materials, widely used in electronics, mold making, aerospace, and other fields. Due to the brittleness and abrasiveness of graphite, graphite engraving and milling machines require special attention during use to ensure efficient and stable operation and extend their service life. Understanding the key points for maintenance and upkeep of graphite engraving and milling machines can help users better use and maintain this precision equipment.

1. Regular Cleaning

Graphite engraving and milling machines generate a large amount of graphite dust during processing. This dust accumulates in various parts of the machine tool, affecting its normal operation and potentially causing electrical system malfunctions. Therefore, regular cleaning is crucial.

External Cleaning: Clean the exterior of the machine tool with a soft cloth, avoiding scratches from hard objects. A slightly damp cloth can be used for gentle wiping, avoiding moisture entering the electrical components.

Processing Area Cleaning: After each processing cycle, graphite dust should be cleaned promptly. Industrial vacuum cleaners or air guns can be used to clean the machining area, guide rails, and other areas prone to dust accumulation.

Electrical System Cleaning: Junction boxes, control panels, and buttons in the electrical system also require regular cleaning. Air guns can be used to blow away dust to prevent dust buildup and potential electrical malfunctions.

2. Lubrication Maintenance

The lubrication system is crucial for the operation of the graphite engraving milling machine. Good lubrication reduces wear on components, improves accuracy, and extends the machine's lifespan.

Lubricating Oil Inspection and Replacement: Regularly check the machine's lubricating oil level and quality. If the oil is found to be deteriorated or insufficient, it should be replaced promptly. Typically, the lubrication system should be checked monthly, and the lubricating oil should be replaced as needed based on equipment usage frequency and environmental conditions.

Lubrication Point Cleaning and Lubrication: Regularly clean dirt from all lubrication points and add appropriate amounts of lubricating oil to sliding guide rails, nuts, and other components. Ensure all moving parts operate smoothly.

Hydraulic System Inspection: Leaks in the hydraulic system of the graphite engraving milling machine can lead to insufficient lubrication, affecting machining accuracy. Regularly check the hydraulic system's seals and replace or repair as necessary.

3. Cooling System Inspection

Graphite engraving milling machines generate a significant amount of heat during machining, especially during high-speed cutting. The coolant system effectively reduces machining temperature, ensuring stability and accuracy during processing. Maintaining the cooling system is crucial.

Coolant Inspection and Replacement: Regularly check the coolant level and quality. Keep the coolant clean to prevent deposits and impurities from affecting cooling performance. Change the coolant monthly, especially after prolonged use or heavy equipment operation.

Coolant Piping Cleaning: Check for blockages in the coolant pipes and clean them if necessary to ensure smooth coolant flow and prevent overheating due to poor cooling.

Pump System Maintenance: Check the coolant pump for proper functioning and regularly clean the pump body and filter to ensure stable pump system operation.

4. Precision Inspection and Adjustment

The precision of graphite engraving milling machines is critical to machining quality, especially in high-precision machining. Even minor errors can affect the product yield. Therefore, regular precision inspection and adjustment are essential.

Bearing and Guide Rail Inspection: Regularly inspect the machine tool's bearings and guide rails for wear. If wear is found, replace the relevant parts promptly to avoid affecting machining accuracy.

Spindle Inspection: Check the spindle's balance and stability. Regularly use high-precision measuring tools to check spindle deviation and adjust or replace the spindle as needed.

Worktable Flatness Inspection: The flatness of the worktable directly affects machining accuracy; therefore, regularly check the worktable's levelness and adjust it using special tools if necessary.

5. Electrical System Inspection

The electrical system is the core of the graphite engraving and milling machine. Any electrical fault can cause the machine to stop or even damage components. Therefore, the maintenance and upkeep of the electrical system is equally important.

Cable and Connector Inspection: Regularly check cables and connectors for aging, wear, or loosening, and repair or replace them promptly.

Electrical Component Cleaning: Use compressed air to clean electrical components, such as the main control board and contactors, to prevent dust accumulation that could lead to short circuits or malfunctions.

Software Updates: Ensure the graphite engraving and milling machine's software is the latest version. Regularly check the control system for available upgrades to improve equipment performance and stability.

6. Operator Training and Management

Proper operation of the graphite engraving and milling machine is crucial for its maintenance. Regularly train operators to ensure they understand the correct operating methods and maintenance requirements.

Operating Procedure Training: Train operators to master the correct operating methods to avoid equipment malfunctions or damage caused by improper operation.

Routine Inspection and Record Keeping: Operators should develop the habit of regularly inspecting the equipment and keeping daily maintenance records. This helps in timely detection of problems when malfunctions occur and provides a basis for repair.

As a high-precision machining equipment, the maintenance and upkeep of graphite engraving milling machines are crucial to ensuring their long-term stable operation. Regular cleaning, lubrication, cooling, precision checks, and electrical system maintenance can effectively extend the equipment's lifespan and improve processing quality and production efficiency. Regular operator training and professional maintenance are also key to ensuring normal equipment operation. Only by performing proper daily maintenance can the graphite engraving milling machine maintain a stable working condition in the production environment.

русский

русский عربى

عربى