Are CNC machine tools difficult to operate? How to get started quickly?

As the manufacturing industry develops towards higher precision and higher efficiency, CNC machine tools have become an indispensable piece of equipment in modern production. Many companies and technicians, when first encountering CNC machine tools, often worry about their operational difficulty, especially compared to traditional manual machine tools. So, is operating a CNC machine tool really that complicated? How can one quickly learn and master its basic operations?

This article will answer these questions and provide some useful advice for beginners.

1. Basic Concepts of CNC Machine Tools

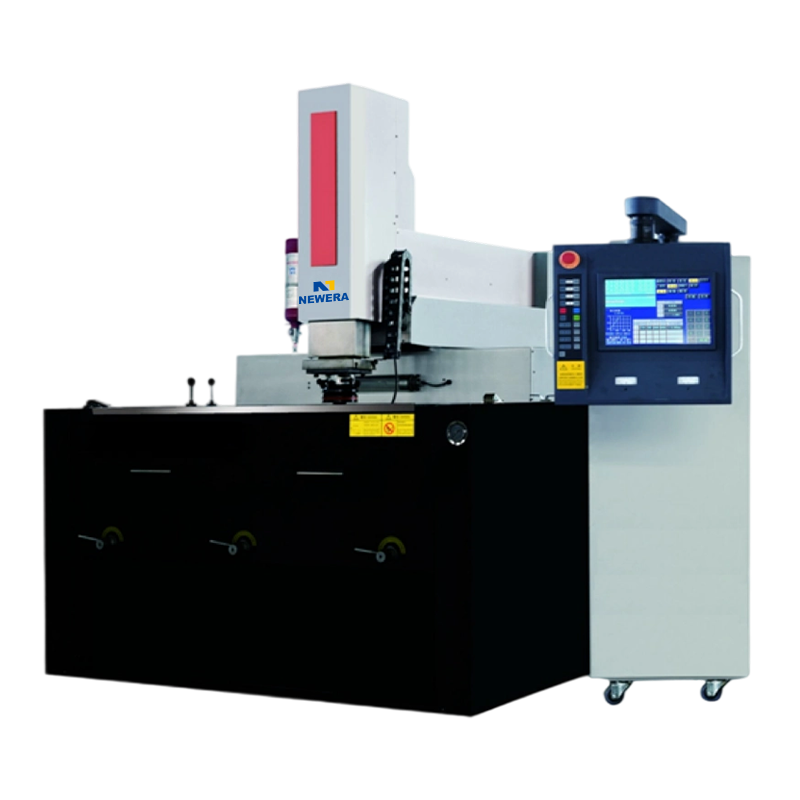

First, understanding the basic concepts of CNC machine tools is the first step to getting started. A CNC machine tool is a machine tool controlled by a computer program, capable of accurately completing machining tasks based on input digital signals. Compared to traditional manual machine tools, CNC machine tools are more automated, enabling high-precision and high-efficiency machining. Common CNC machine tools include CNC milling machines, CNC lathes, and CNC grinding machines.

Although operating CNC machine tools requires a certain level of technical skill, its essence is the conversion of machine operations into digital input, which is then automated through computer programs. Therefore, for beginners, mastering basic operation and programming skills is key to quickly getting started.

2. Analysis of the Difficulties in Operating CNC Machine Tools

While operating CNC machine tools is more precise and automated than traditional machine tools, the main difficulties for beginners lie in the following aspects:

Programming and Understanding: The working principle of CNC machine tools relies on the writing of G-code (or M-code) programs. This requires operators to understand the programming language and how various instructions affect machine movement.

Equipment Setup and Debugging: Before operating a CNC machine tool, certain equipment settings are required, such as workpiece positioning, tool installation, and parameter debugging. These settings directly affect the accuracy and quality of machining.

Understanding the User Interface: CNC machine tools are usually equipped with touchscreens or button control panels. Beginners may find the complex interface confusing and need time to familiarize themselves with the various buttons and displayed content.

Troubleshooting and Repair: During machining, operational or equipment malfunctions may occur, such as tool wear or program errors. New users need certain troubleshooting skills.

3. How to Quickly Get Started with CNC Machine Tools

Although the learning curve for CNC machine tools is steep, beginners can quickly master their basic operations and gradually improve their skills through the following methods.

1) Basic Training and Learning

The first step to getting started with CNC machine tools is to attend a professional training course. Many companies and training institutions offer CNC machine tool operation and programming training courses. Through professional training, you can more systematically master the operation procedures and programming skills of CNC machine tools. In addition, there are many free learning resources and video tutorials online, suitable for beginners to learn independently.

2) Familiarizing Yourself with the Operating Interface and Common Functions

Before starting to operate a CNC machine tool, you first need to familiarize yourself with its operating interface. Understanding the various buttons, switches, and information on the display screen will help you operate the machine more efficiently. Generally, the operating interface of a CNC machine tool will include manual operation mode, automatic machining mode, and parameter setting interface. Familiarity with these basic functions helps avoid misoperation.

3) Gradually Learn G-Codes and M-Codes

G-codes (geometric commands) and M-codes (program commands) are the core of CNC programming. For beginners, it's not necessary to master complex programs immediately; start by learning some basic G-codes and M-codes. For example, G00 is used for rapid positioning, G01 for linear interpolation, and G02 and G03 for circular interpolation. After understanding these basic instructions, you can test and verify your understanding by writing simple programs.

4) Practice and Accumulate Experience

The most effective way to learn CNC machine tool operation is through practice. Through actual operation, you can more intuitively understand the machine's movement and working principles. Start with simple tasks, such as machining some simple geometric shapes, and gradually move on to more complex machining projects. As your operation deepens, you will become more familiar with the equipment's operating procedures and parameter adjustment techniques.

5) Refer to the Operation Manual and Technical Support

Referring to the machine's operation manual is crucial when using CNC machine tools. Each machine tool has different operating methods, program settings, and precautions. The operation manual can not only help you answer common operating questions but also guide you in troubleshooting. In addition, many CNC machine tool manufacturers offer technical support, and you can seek help from professional technicians when you encounter difficulties.

4. Common Problems and Solutions

Beginners may encounter some common problems when operating CNC machine tools. Here are some typical problems and their solutions:

Program Errors: If a program error occurs, first check if the G-code and M-code are correct, and confirm that the program has no missing instructions or input errors. Check the program's rationality through simulation machining and simulation functions.

Inaccurate Workpiece Positioning: Inaccurate workpiece positioning may cause machining errors. Ensure that the workpiece is correctly fixed and aligned with the coordinate axes before operation.

Tool Wear or Damage: Tools may wear or be damaged after prolonged use. Regularly check the condition of the tools and replace them with new tools if necessary.

Although operating CNC machine tools can be challenging for beginners, with systematic learning and practice, everyone can quickly learn and master the basic operations. Attending training courses, familiarizing oneself with the operating interface, learning basic programming knowledge, and continuously accumulating practical experience are effective ways to improve CNC machine tool operation skills. As your operational skills improve, you will be able to handle complex machining tasks more easily and achieve high-efficiency and high-precision machining goals in the manufacturing process.

русский

русский عربى

عربى