Are CNC Machines Suitable for Small Factories?

In the manufacturing industry, CNC machines have become core equipment for improving production efficiency and product quality. However, many small factory owners have questions before investing: "Are CNC machines really suitable for small factories? Are the costs and maintenance worthwhile?"

This article will provide a detailed analysis from the perspectives of equipment characteristics, application value, economics, and practical suggestions.

1. Advantages of CNC Machines

A CNC machine is a mechanical device that controls the machining process through a computer program, possessing the following core advantages:

High Precision and Repeatability

CNC machines can strictly execute machining actions according to the program, with minimal repetitive machining errors. This is especially important for small-batch, high-precision parts production.

Integrated Machining Processes

Modern CNC machines can perform multiple machining processes such as turning, milling, drilling, and tapping. One machine can replace multiple traditional machine tools, saving workshop space and labor costs.

Automation and Reduced Manpower

Through program control, CNC machines achieve unattended or semi-automatic production, reducing reliance on manual labor and improving production efficiency.

Adaptability to Complex Part Machining

For curved surfaces, irregular shapes, or precision parts, CNC machines can perform precise machining, which is difficult to achieve with traditional manual machine tools.

2. The Value of Choosing CNC Machines for Small Factories

Although CNC machines are more expensive than traditional machine tools, they still offer significant value for small factories:

Improved Production Efficiency: Small factories often have limited manpower; CNC machines can complete more machining tasks while reducing the number of operators.

Guaranteed Product Quality: In small-batch custom production, CNC machines can ensure consistent product dimensions and reduce the scrap rate.

Expanded Business Scope: With CNC capabilities, small factories can undertake higher value-added orders, such as precision parts or mold processing.

Saving Space and Equipment Costs: One CNC machining center can replace multiple traditional machine tools, requiring less space and offering centralized maintenance.

3. Key Considerations for Small Factories When Purchasing CNC Machine Tools

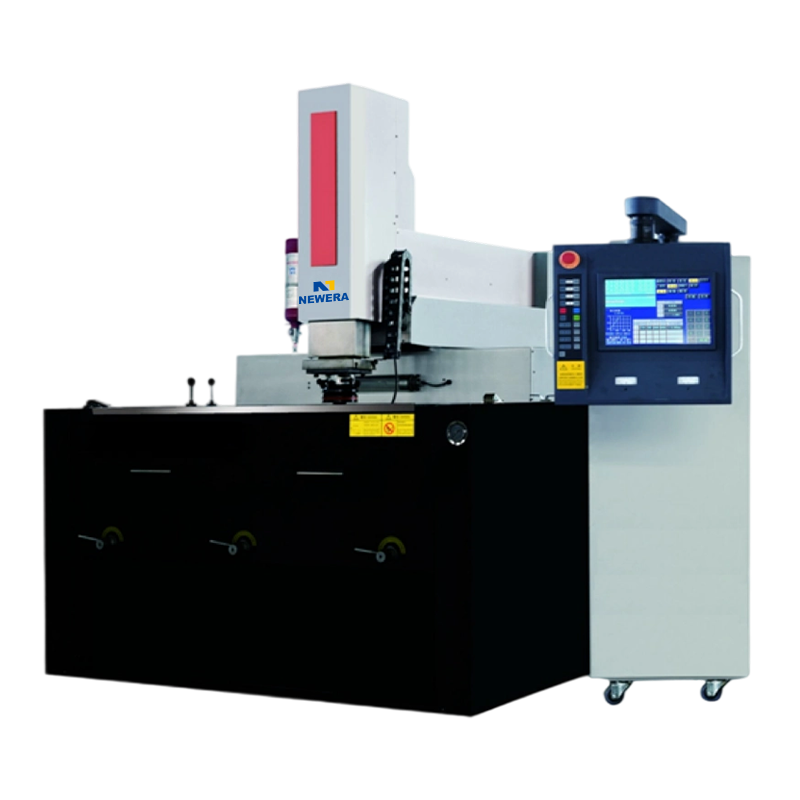

Equipment Type Matching Factory Needs

Small factories can choose based on the type and volume of parts produced:

CNC Lathes: Suitable for shaft-type parts

CNC Milling Machines/Machining Centers: Suitable for flat, curved, and complex parts

CNC Multi-functional Machine Tools: Suitable for small factories with low-volume, high-variety products

Investment and Return Assessment

CNC machine tools are not inexpensive, but they can quickly pay for themselves by increasing output, reducing scrap rates, and saving on labor costs. It is recommended to calculate the ROI (Return on Investment) before purchasing.

Operator Training

Operating CNC machine tools requires certain skills. Small factories can train existing employees or hire skilled operators to ensure the equipment is fully utilized.

Maintenance and After-Sales Service

Choose a brand with comprehensive after-sales service and easy maintenance to ensure long-term stable operation of the equipment and reduce downtime losses.

4. Practical Cases of CNC Machine Tools Suitable for Small Factories

In small factories involved in metal processing, hardware manufacturing, mold processing, etc., CNC machine tools have been widely used:

A small bearing parts processing factory increased production efficiency by 30% and reduced the scrap rate by 15% after using CNC lathes.

A hardware accessories factory integrated multiple traditional machines through a CNC machining center, achieving mass customization production, and increasing business revenue by 25%.

These cases show that even for small factories, as long as the model and process are reasonably selected, CNC machine tools can still bring significant benefits.

CNC machine tools are perfectly suitable for small factories, provided that they choose equipment that matches their production needs and properly manage operator training and maintenance. They can not only improve production efficiency and product accuracy but also help small factories expand into high-value-added businesses and achieve sustainable development. Choosing a model that suits your production scale and process needs is crucial to truly realize the value of CNC machine tools, rather than blindly following trends.

русский

русский عربى

عربى