How to Improve Production Line Automation with Horizontal Machining Centers?

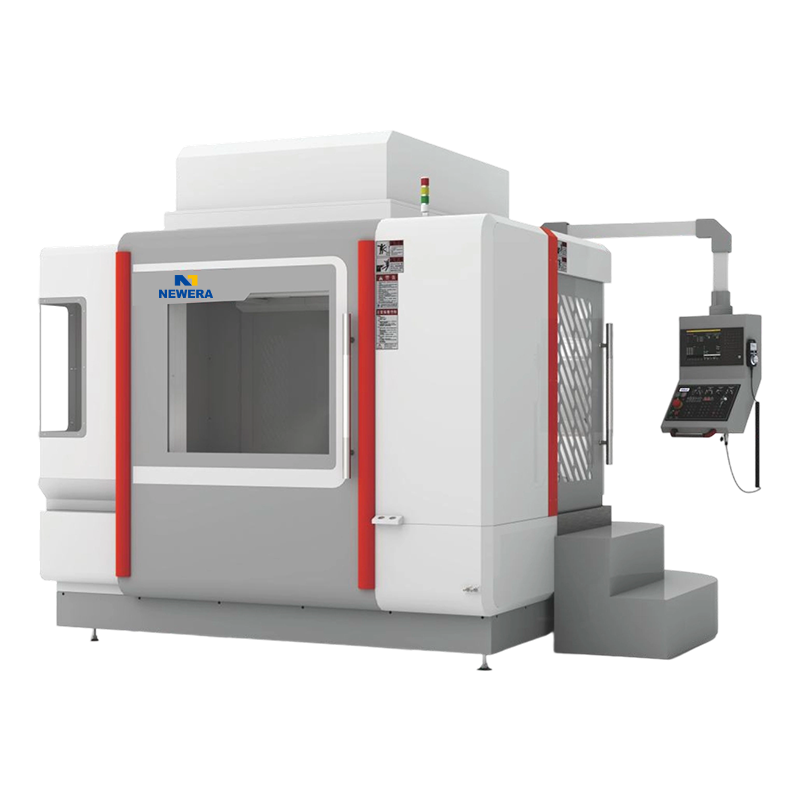

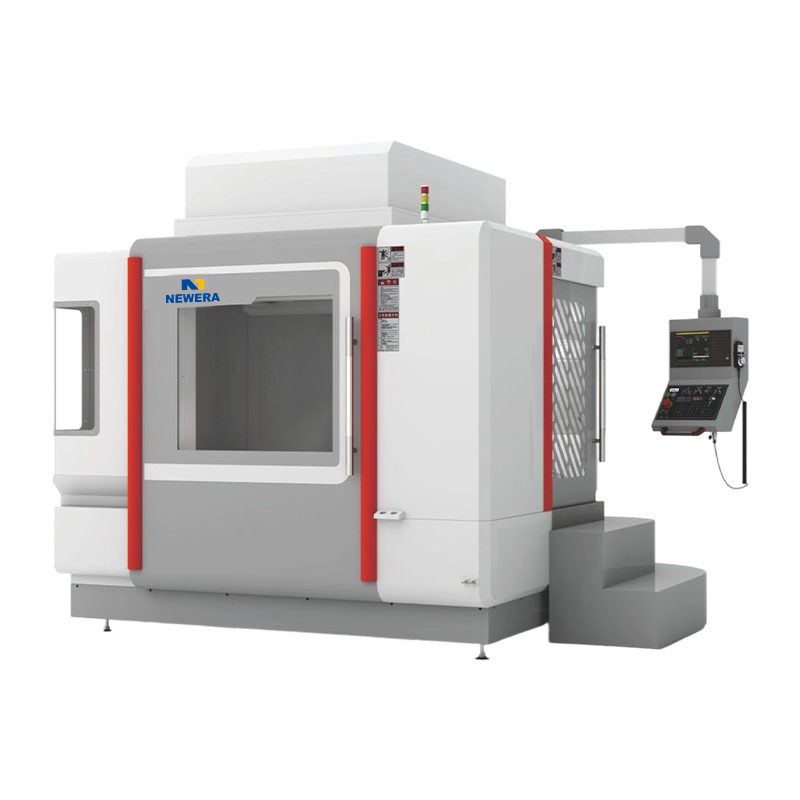

With the continuous development of the manufacturing industry, enterprises have placed higher demands on the efficiency, precision, and flexibility of production lines. As an important high-precision machining equipment in modern manufacturing, horizontal machining centers are widely used in the automotive, aerospace, mold manufacturing, and other fields due to their excellent machining capabilities and high level of automation. By rationally configuring and optimizing the use of horizontal machining centers, enterprises can effectively improve the automation level of production lines, increase production efficiency, reduce human error rates, and ensure the stability of machining quality.

1. Characteristics and Automation Advantages of Horizontal Machining Centers

Horizontal machining centers typically have a horizontally placed worktable, enabling multi-axis, three-dimensional machining. They can simultaneously perform milling, drilling, tapping, and other machining operations. This versatility gives horizontal machining centers a significant advantage in automated production lines.

The main characteristics of horizontal machining centers include:

High rigidity and high stability: Horizontal machining centers have strong cutting capabilities and high stability, making them suitable for batch processing and precision machining. They can maintain accuracy under long-term high loads.

High Precision and High Efficiency: Through CNC system control, horizontal machining centers achieve high-precision machining, reducing human error.

Automatic Tool Changer: Most horizontal machining centers are equipped with automatic tool changers, which can automatically switch tools according to different workpiece machining requirements, further improving machining efficiency.

Multi-Axis Machining Capability: Horizontal machining centers typically have multiple working axes (e.g., three-axis, five-axis), allowing simultaneous machining in multiple directions, significantly improving machining efficiency and part accuracy.

2. Configuring an Automated Control System

To maximize the automation level of the production line, an advanced automated control system is essential. The CNC system of a horizontal machining center is the core of automation, precisely controlling the machine tool's motion trajectory and cutting path to ensure consistent machining quality and precision.

Specific methods include:

Introducing an Advanced CNC System: Selecting a high-performance, open-architecture CNC system, such as FANUC, Siemens, or Heidenhain, provides efficient and flexible programming and operation interfaces, and supports remote monitoring and fault diagnosis.

Integrating an Intelligent Monitoring System: Combining Industrial Internet of Things (IoT) technology allows for real-time monitoring of the horizontal machining center's operating status, including equipment operation, temperature, and pressure. Data acquisition and analysis enable early detection of potential problems, predictive maintenance, and prevention of sudden failures.

Automated Programming and Optimization: Modern CNC systems support automated programming functions, automatically generating machining programs through CAM (Computer-Aided Manufacturing) software, reducing manual programming time and avoiding human error. Furthermore, intelligent algorithms can optimize processing paths and improve processing efficiency.

3. Construction of Automated Supporting Systems

To further enhance the automation level of horizontal machining centers, enterprises also need to build automated supporting systems, such as automatic feeding, automatic unloading, automatic measurement and inspection, and automatic tool changing. These supporting systems, used in conjunction with the horizontal machining center, can achieve full automation of the production process, greatly improving production efficiency and product quality.

Key automated supporting systems include:

Automatic Feeding and Unloading System: Raw materials are fed into the machine tool via robotic arms, robots, or automated conveyor systems, and the workpiece is automatically removed after processing, avoiding manual intervention and improving the automation level of the production line. For example, robots are used to place workpieces into the machining center, unload them, and then send them to the next process or packaging stage.

Automatic Tool Magazine and Tool Changing System: In horizontal machining centers, the automatic tool changing system is an important component for improving automation. The automatic tool magazine can automatically select the appropriate tool according to the needs of the machining program and quickly complete the tool change, avoiding the time wasted by manual tool changing and potential errors.

Automated Measurement and Quality Control: Automated measurement systems are essential to ensure machining accuracy and quality. Integrating online measurement devices (such as laser measurement systems or touch probes) enables real-time detection of workpiece dimensions during machining, ensuring they meet design requirements. If dimensional deviations are detected, the system automatically adjusts machining parameters to maintain part consistency and precision.

4. Integrated Intelligent Systems

Integrating intelligent systems is key to improving the automation level of horizontal machining centers. By combining with technologies such as artificial intelligence, machine learning, and big data analytics, enterprises can achieve more flexible and intelligent production methods.

Intelligent system integration methods include:

Production Scheduling and Intelligent Decision-Making: Through intelligent production scheduling systems, combining information such as work orders, equipment status, and production progress, production processes and resource allocation are optimized, reducing waiting time and equipment idle time, and improving overall production efficiency.

Predictive Maintenance and Self-Diagnosis: Utilizing big data analytics and machine learning algorithms, the system can monitor the operating status of equipment in real time and predict potential failures. This predictive maintenance method not only avoids equipment failures but also significantly reduces downtime, ensuring production continuity.

Adaptive Machining and Optimization: The intelligent system can automatically optimize machining parameters, such as feed rate and depth of cut, based on the different characteristics of the workpiece (e.g., material, shape, size), thereby improving machining quality and reducing energy consumption.

5. Practical Cases of Horizontal Machining Centers

In practical applications, many industries have begun to utilize horizontal machining centers to enhance the automation level of their production lines. For example:

Automotive Manufacturing: In automotive parts processing, the combination of horizontal machining centers and automated assembly lines significantly improves production efficiency, reduces manual operation, and enhances the precision and consistency of parts.

Aerospace: In the processing of aero-engine components, horizontal machining centers, through multi-axis linkage machining, can efficiently complete the processing of complex parts. Simultaneously, in conjunction with automated inspection systems, they ensure the precision requirements of each component.

Mold Manufacturing: Mold processing requires high precision and efficiency. Horizontal machining centers, combined with automatic tool changers and automatic measurement systems, can quickly complete mold processing, shorten delivery cycles, and reduce manual intervention.

By rationally configuring horizontal machining centers and their automated supporting systems, enterprises can significantly improve the automation level of their production lines, achieving efficient and precise production processes. This not only improves production efficiency and reduces production costs but also ensures the stability and consistency of product quality.

русский

русский عربى

عربى